Global

International

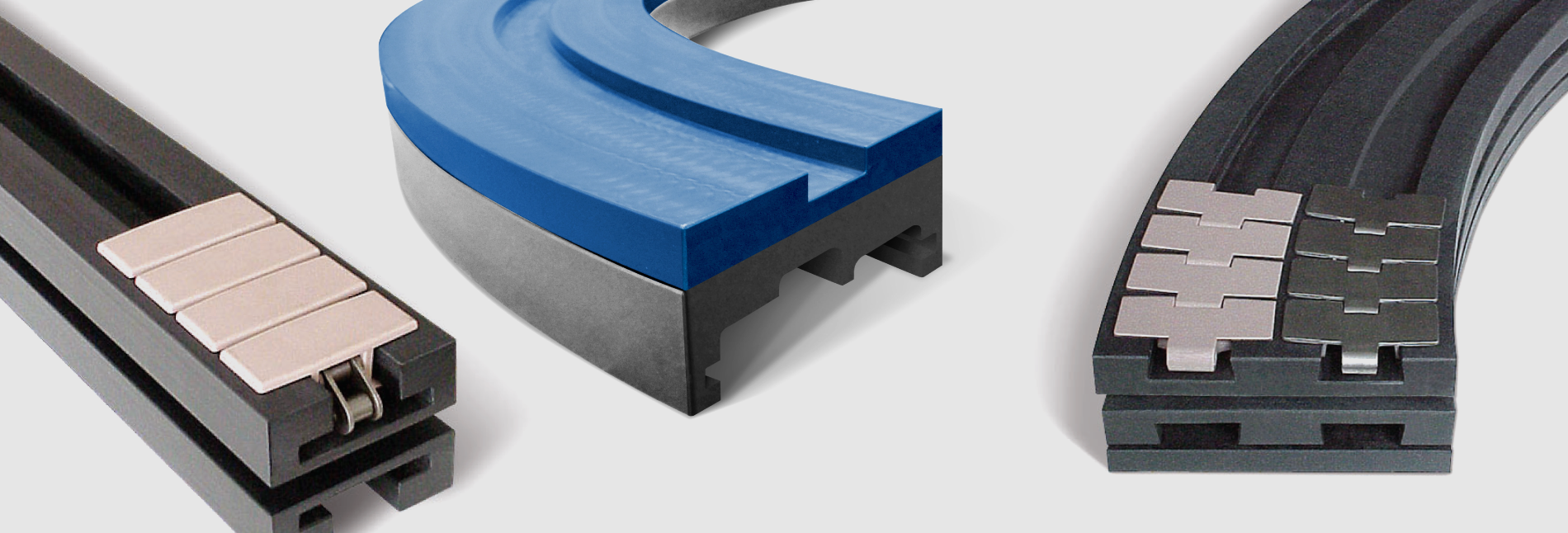

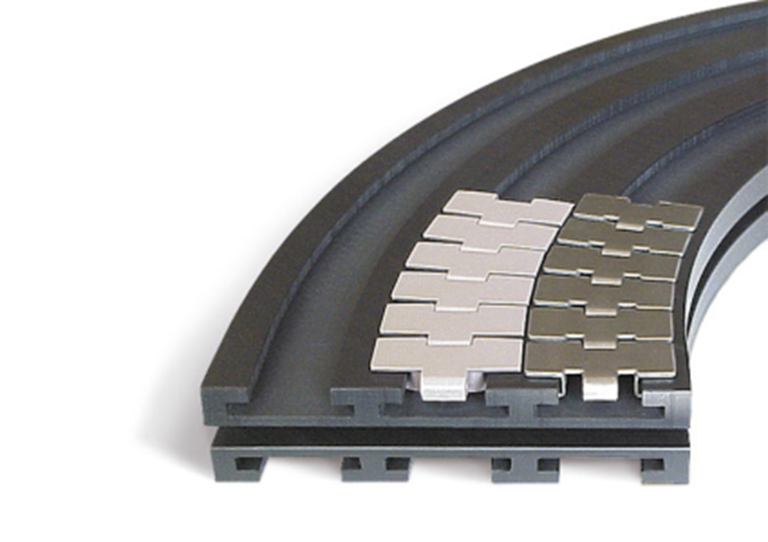

Our Curves, Magnetic Curves, and Straight Tracks are engineered to guide side-flexing steel and plastic conveyor chains with low friction, low noise, precision and efficiency. These customizable components ensure smooth and consistent material handling while minimizing wear and tear on conveyor chains.

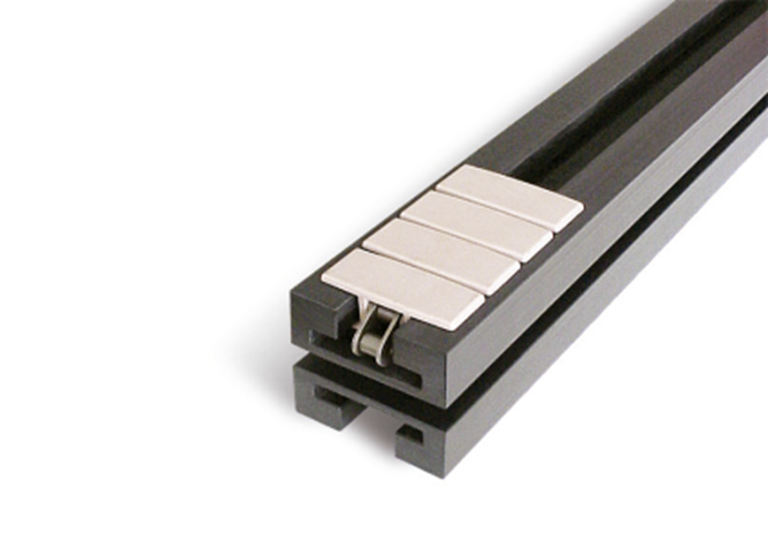

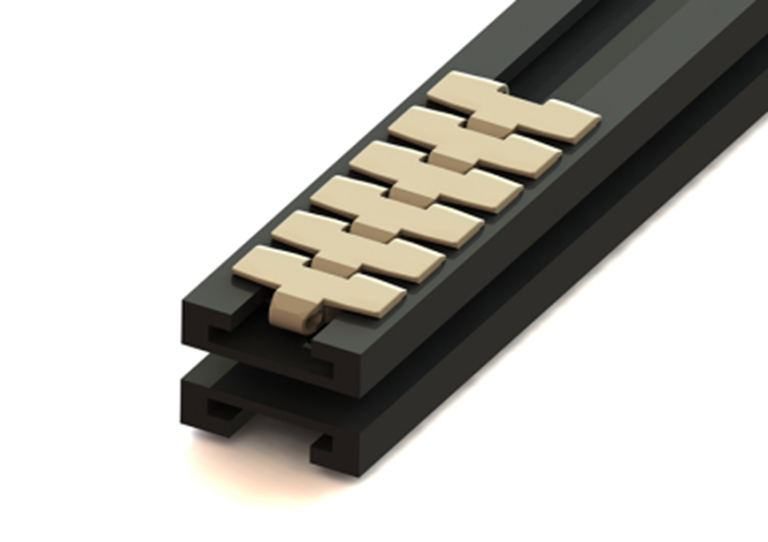

Our selection of straight tracks helps to keep your conveyor chains running smoothly by reducing friction and wear.

These tracks are designed to work with snap-on TAB chains. The main purpose of these tracks is to securely hold the chains in place, preventing lateral movement and maintaining alignment during conveying operations. Snap-on chains and tracks are commonly used in applications where quick installation, removal, or adjustment of the chain is necessary.

Specifications

These tracks are specifically tailored for 882 TAB Chains providing a precise guiding and positioning for the 882 TAB chains. The 882 TAB chain and tracks are often utilized in industries where reliable and accurate product transportation is vital, such as in food processing, bottling and other production lines.

Specifications

These tracks are used with bevel chains. Bevel chains have an angled or beveled hinge that match the shape of the track. The purpose of the track is to ensure proper engagement and alignment of the bevel chain, facilitating smooth and efficient transfer of products.

Specifications

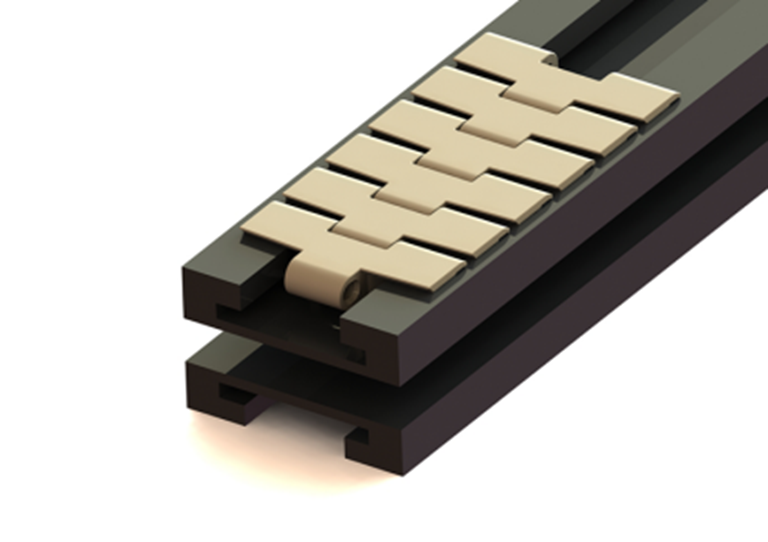

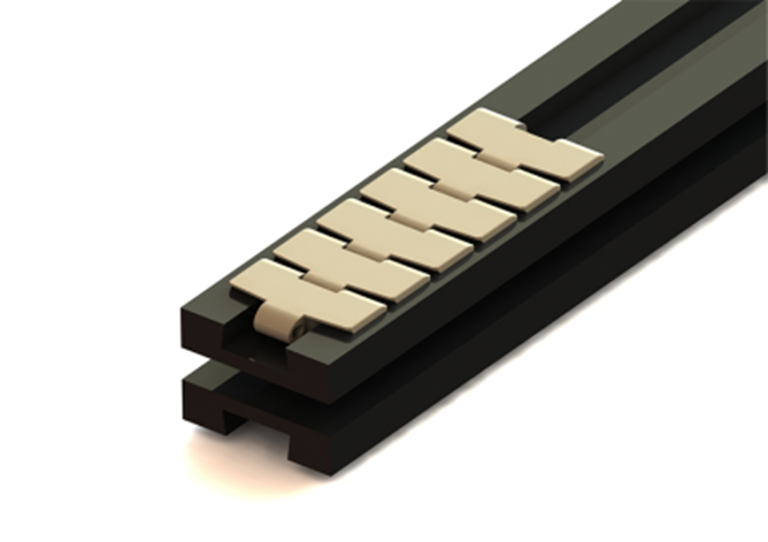

These tracks are designed to work specifically with TAB chains. These chains have tabs on the bottom that engage with the straight tracks, allowing for smooth and precise movement along the conveyor system. TAB chains are commonly used in applications that require accurate positioning and indexing of products.

Specifications

Curves are an essential component of any side flexing chain conveyor. Our selection of curves includes various sizes to fit your specific needs.

The primary purpose of these curves is to securely hold snap-on TAB chains in place while allowing for smooth turning operations on the conveyor. These curves ensure that the chains remain aligned and engaged, preventing any lateral or unwanted movement during conveying.

Specifications

Variants:

On Demand Options

These curves play a crucial role in guiding and positioning 882 TAB chains during directional changes on the conveyor. They are specifically designed to keep the chains in place while ensuring reliable and accurate product transportation.

Specifications

Variants:

On Demand Options

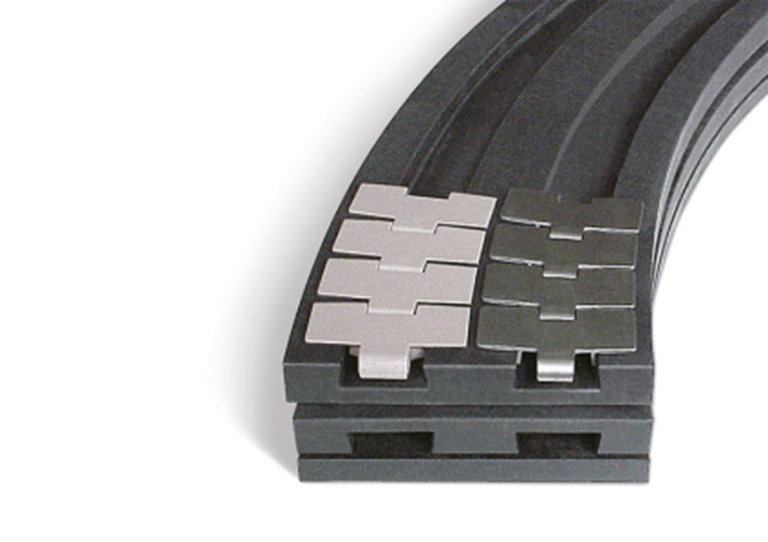

Bevel curves are essential for maintaining the alignment and stability of bevel chains as they navigate curved sections of the conveyor. These curves securely hold the bevel chains in place, ensuring smooth and efficient transfer of products while preventing any lateral movement.

Specifications

On Demand Options

These curves are specifically designed to securely hold TAB chains in place while facilitating smooth directional changes on the conveyor system. They ensure accurate positioning of products during turns, keeping the chains properly engaged and aligned.

Specifications

On Demand Options

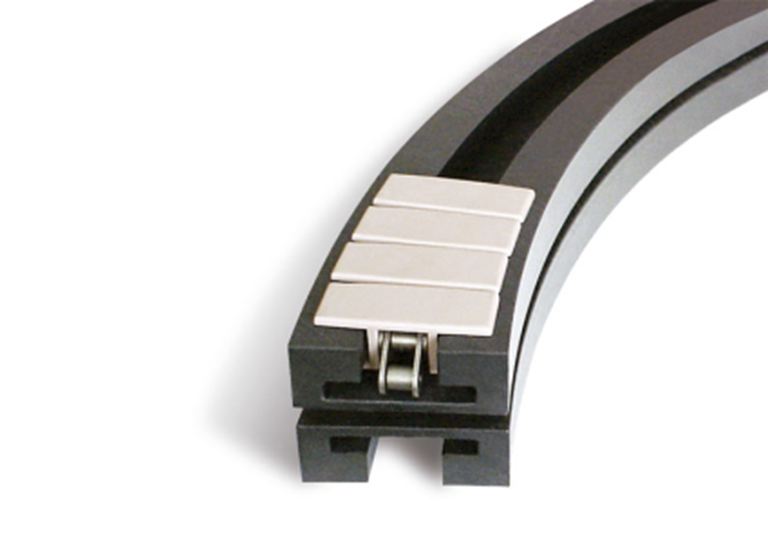

Magnetic curves are ideal to any side flexing magnetic chain conveyor. This system makes easier the cleaning and maintenance of the conveyor. Our selection includes various sizes and materials to suit your application.

The purpose of a magnetic curve is to attract and maintain alignment of the “255 FT M” chains as they travel through the curve on the conveyor system. The magnetic force helps keep the chains securely in place, providing easy maintenance and cleaning advantages. This magnetic attraction ensures smooth and reliable movement of the chains around the curve, enhancing the overall efficiency of the conveyor system.

Specifications

Variants:

On Demand Options

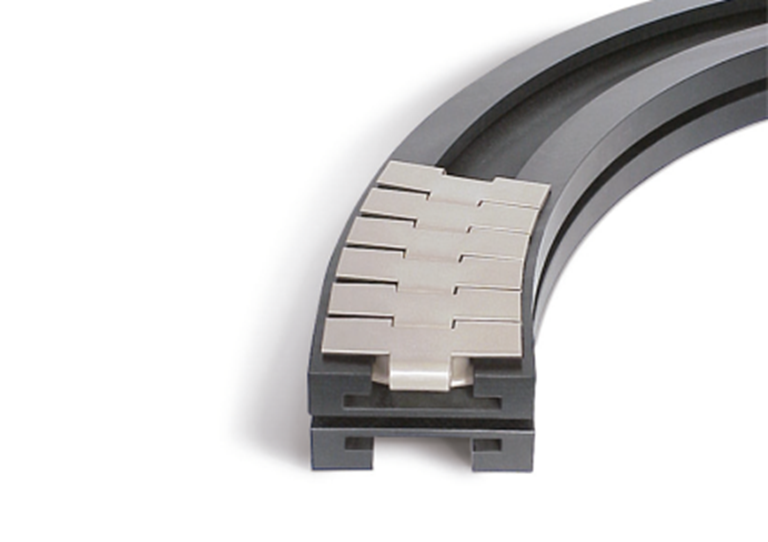

The purpose of a magnetic curve is to attract and maintain alignment of these chains as they travel through the curve on the conveyor system. The magnetic force helps keep the chains securely in place, providing easy maintenance and cleaning advantages. This magnetic attraction ensures smooth and reliable movement of the chains around the curve, enhancing the overall efficiency of the conveyor system.

Specifications

Variants:

On Demand Options

The purpose of a magnetic curve is to attract and maintain alignment of the “882 M LBP” chains as they travel through the curve on the conveyor system. The magnetic force helps keep the chains securely in place, providing easy maintenance and cleaning advantages. This magnetic attraction ensures smooth and reliable movement of the chains around the curve, enhancing the overall efficiency of the conveyor system.

Specifications

Variants:

On Demand Options

The purpose of a magnetic curve is to attract and maintain alignment of the “882 M” chains as they travel through the curve on the conveyor system. The magnetic force helps keep the chains securely in place, providing easy maintenance and cleaning advantages. This magnetic attraction ensures smooth and reliable movement of the chains around the curve, enhancing the overall efficiency of the conveyor system.

Specifications

Variants:

On Demand Options

The purpose of a magnetic curve is to attract and maintain alignment of these chains as they travel through the curve on the conveyor system. The magnetic force helps keep the chains securely in place, providing easy maintenance and cleaning advantages. This magnetic attraction ensures smooth and reliable movement of the chains around the curve, enhancing the overall efficiency of the conveyor system..

Specifications

Variants:

On Demand Options

The purpose of a magnetic curve is to attract and maintain alignment of the “881 M” chains as they travel through the curve on the conveyor system. The magnetic force helps keep the chains securely in place, providing easy maintenance and cleaning advantages. This magnetic attraction ensures smooth and reliable movement of the chains around the curve, enhancing the overall efficiency of the conveyor system.

Specifications

Variants:

On Demand Options

The purpose of a magnetic curve is to attract and maintain alignment of these chains as they travel through the curve on the conveyor system. The magnetic force helps keep the chains securely in place, providing easy maintenance and cleaning advantages. This magnetic attraction ensures smooth and reliable movement of the chains around the curve, enhancing the overall efficiency of the conveyor system.

Specifications

Variants:

On Demand Options