Global

International

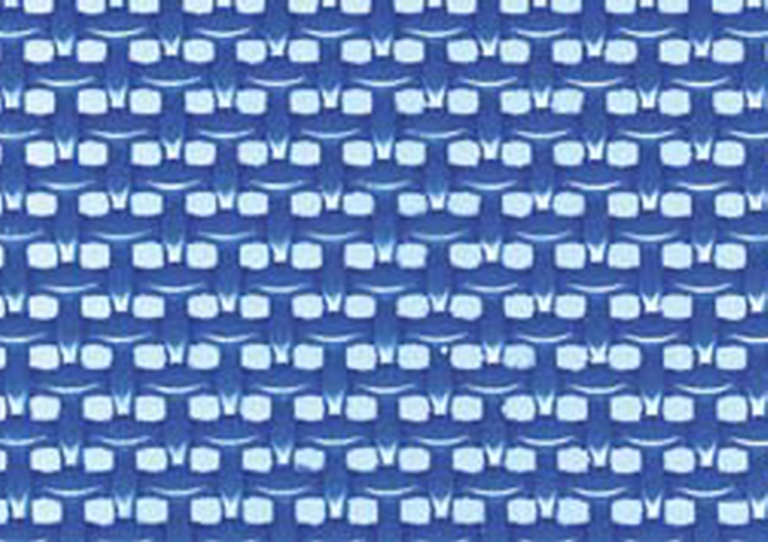

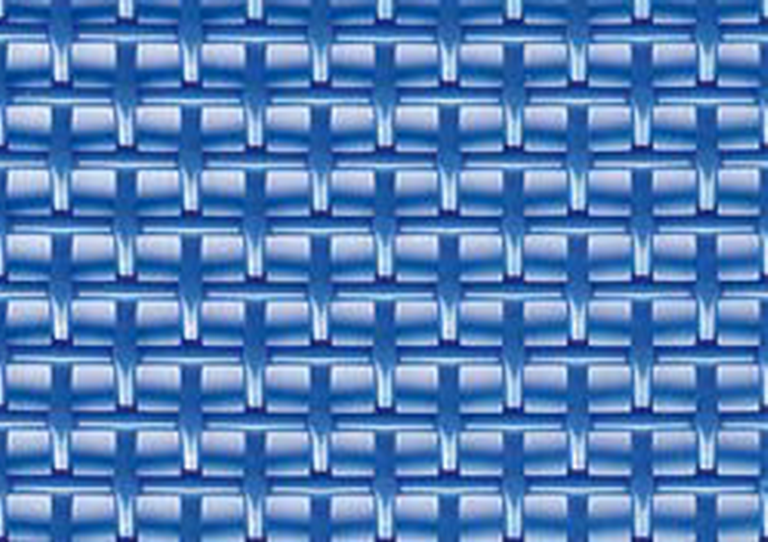

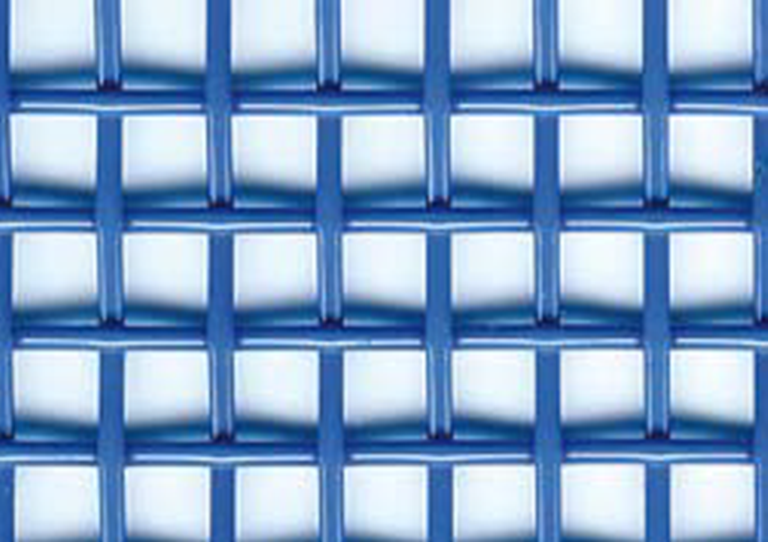

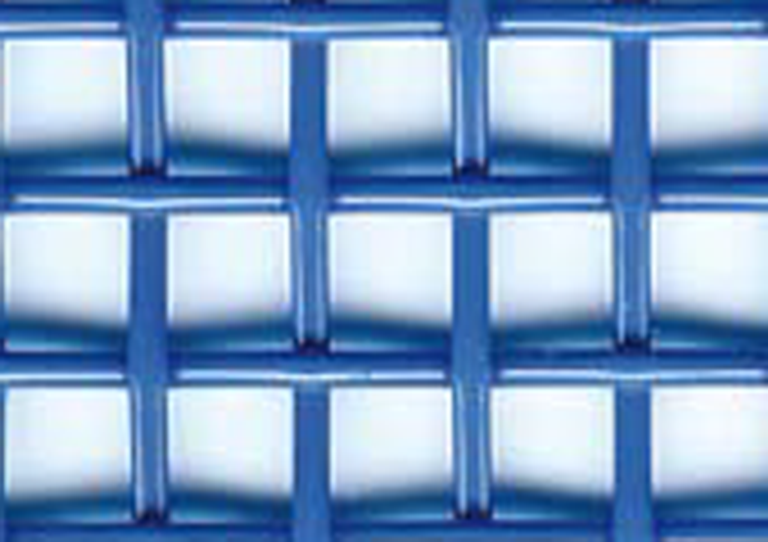

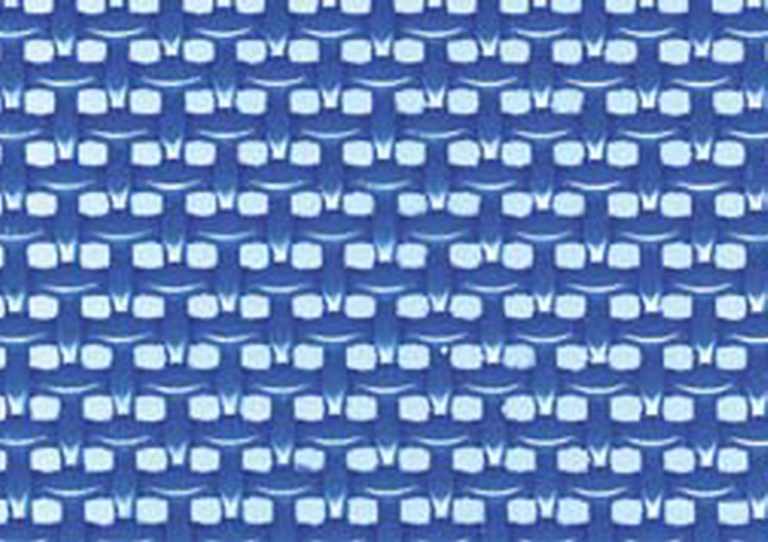

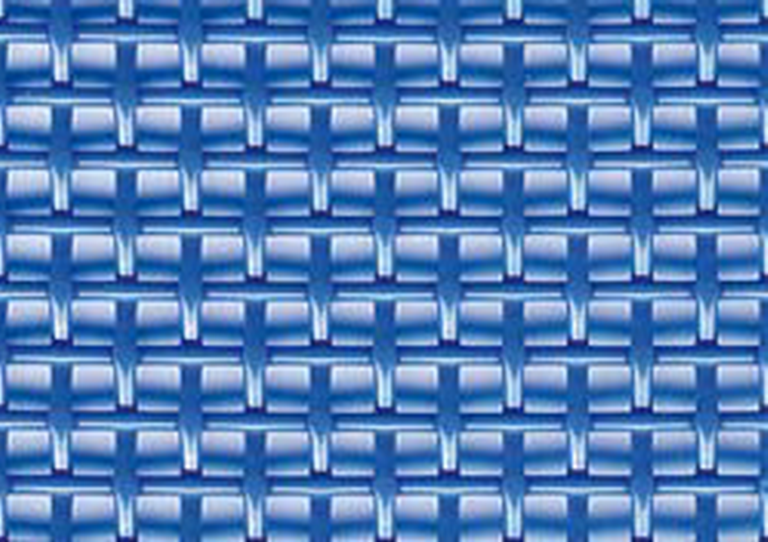

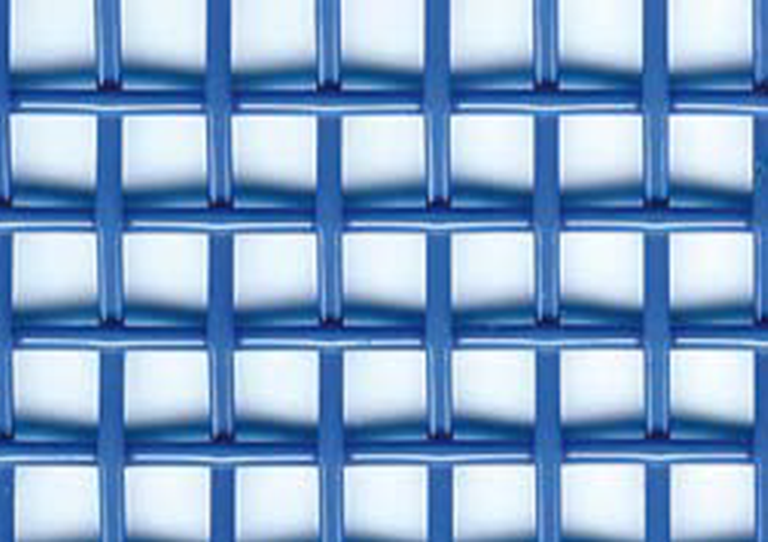

The main application of Ammeraal Beltech Ultrascreen Belts is the de-watering and drying of washed fresh cut vegetables. Various different mesh sizes of the screen material allow the perfect solution for each product size. Combined with a large open area the result is the highest possible production output.

Ultrascreen Belts are also used in cooling processes, recycling of used washing water, waste water treatment, filtering, sieving and squeezing.

Benefits:

NEW IN: Ultrascreen is available with Metal Detectable XMD edges

NEW IN: Ultrascreen PRO for lower total cost of ownership

*Depending on mesh size

*Depending on mesh size

*Depending on mesh size

*Depending on mesh size

Ultrascreen PRO comes with a variety of different teeth and sprocket styles to fit your application. The positive drive system has the following benefits:

The Ultrascreen PRO belts can be installed on new positive drive conveyors or as retrofits on friction-driven conveyors.

Ultrascreen PRO comes with a variety of different teeth and sprocket styles to fit your application. The positive drive system has the following benefits:

The Ultrascreen PRO belts can be installed on new positive drive conveyors or as retrofits on friction-driven conveyors.

Ultrascreen PRO comes with a variety of different teeth and sprocket styles to fit your application. The positive drive system has the following benefits:

The Ultrascreen PRO belts can be installed on new positive drive conveyors or as retrofits on friction-driven conveyors.

Every segment of the Food Industry runs the risk of foreign body contamination, with heavy consequences that include everything from disruptive claims affecting the brand reputation, all the way to very expensive product recalls. For those reasons, we have the Ultrascreen XMD edges available. The edges are X-ray and metal-detectable. Should the edges or cleats pollute your product, it will be picked up by your metal detector.

*Depending on mesh size

Every segment of the Food Industry runs the risk of foreign body contamination, with heavy consequences that include everything from disruptive claims affecting the brand reputation, all the way to very expensive product recalls. For those reasons, we have the Ultrascreen XMD edges available. The edges are X-ray and metal-detectable. Should the edges or cleats pollute your product, it will be picked up by your metal detector.

*Depending on mesh size

Every segment of the Food Industry runs the risk of foreign body contamination, with heavy consequences that include everything from disruptive claims affecting the brand reputation, all the way to very expensive product recalls. For those reasons, we have the Ultrascreen XMD edges available. The edges are X-ray and metal-detectable. Should the edges or cleats pollute your product, it will be picked up by your metal detector.

*Depending on mesh size

*Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, colour and material combination for your specific requirements and local stock availability.