Global

International

Modern high performance corrugators produce very large volumes. Leading Original Equipment Manufacturers and End Users choose Ammeraal Beltech belting solutions for their reliability and safe processing.

We offer heavy-duty uni Modular Belts for paper-reel handling, process belts for use on corrugator machines, uni Modular Belts for stack transportation systems and industry-specific process belts for converting.

Explore using the drop-down menu or by clicking on the pointers

This infographic is used as a general indicative example only.

Actual factory and process configurations could vary, but our industry experts know them all.

If you need it, we’ve got it – Ammeraal Beltech offers the widest range of conveyor and process belts to fulfill all the application requirements of the Corrugated Board and Box-Making Industry.

Paper-reels are moved to the Corrugator, where the process of corrugating starts. Modular XLB provides the reels to the unwinders.

This high-speed (up to 400 m/min) process involves lifting freshly glued, single-faced web to the bridges. For this step, belts are often paired in a 'sandwich' construction.

This application requires conveying of single-faced web onto and across the bridge on the way to gluing and laminating.

This process involves precise product positioning onto and downstream break conveyor belt; perforated, friction-resistant and wear-resistant belts and vacuum-system slider beds are used for faultless sheet control.

This step includes shingling / sheet alignment, separation and transport to one of a number of stackers. Control of sheet movement is of paramount importance here.

The transport of the stacks from the stacker belt can be done with belts that increase efficiency and reduce both waste and the risk of worker injury.

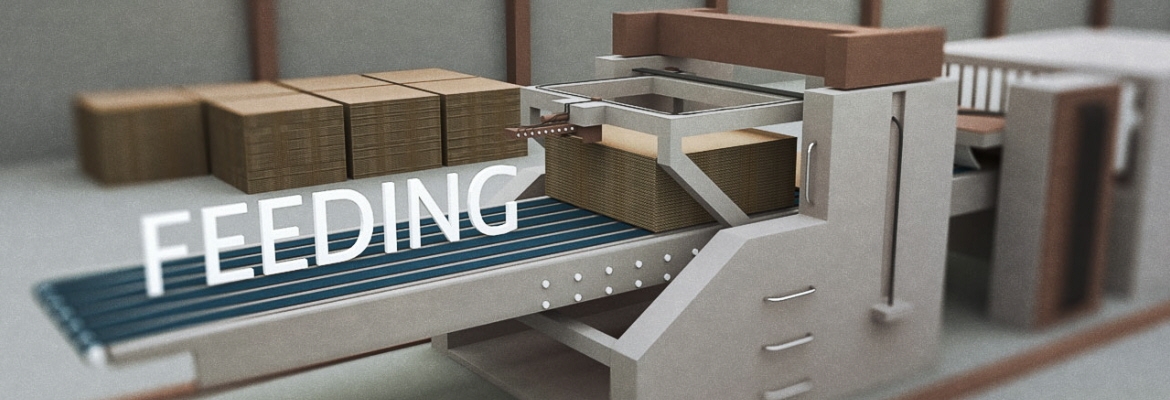

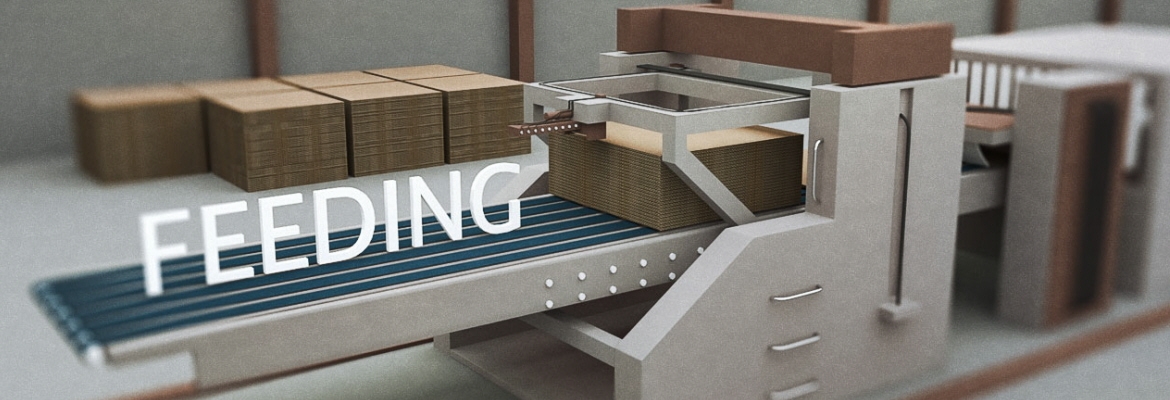

(Pre-)feeders deliver a continuous supply of sheets for further processes; among other machines, they feed into Flexo Folder Gluers and case makers.

The folding section requires special belts for an accurate fold of the blanks. Ammeraal Beltech Flexo Folder Belts have positive grip surfaces to eliminate slippage and jams.

Many different types of process belts for various machine-types and processes are available. Infeed belts (timing belts, vacuum belts, flat belts etc.) pushing the sheets into the converting machine. Transfer belts and transport belts plunge the sheets through the printing units.

Product waste

Machine down time

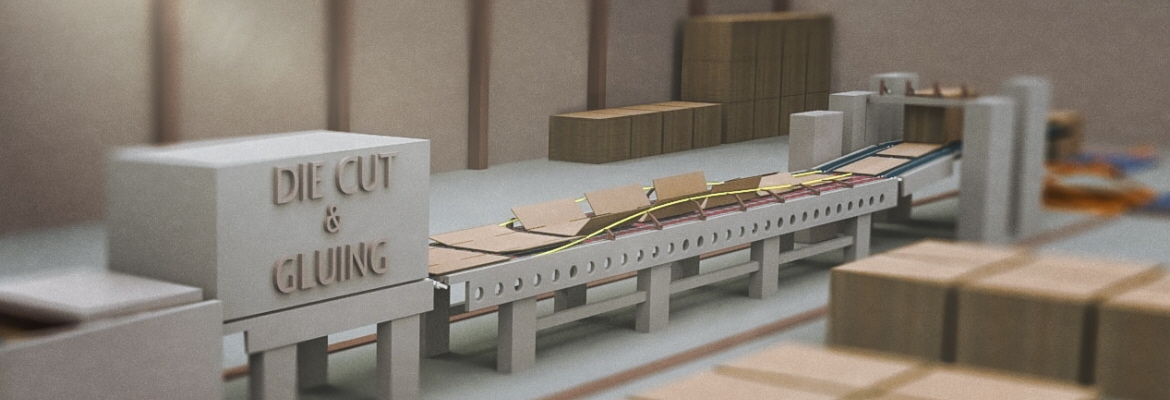

In this part of the production process, the corrugated sheets undergo printing before being shaped into boxes.

Blanks are fed into the machine and moved through it by means of transport and folder gluer belts.

*Recommended Products are some examples of our solutions in a specific process. Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, colour and material combination for your specific requirements and local stock availability.

By continuing to browse our website you agree to our use of cookies and Privacy Policy. More information about cookies.