Global

International

In the Bakery Industry, you're looking for production consistency, quality, shelf lifetime, waste reduction and, of course, Food Safety! What's more, you need this day in and day out, every production shift, because downtime is costly and disruptive.

Our Food Grade certified belts deliver consistently reliable performance and are designed to cut down on waste and eliminate any risk of contamination.

Explore using the drop-down menu or by clicking on the pointers

This infographic is used as a general indicative example only.

Actual factory and process configurations could vary, but our industry experts know them all.

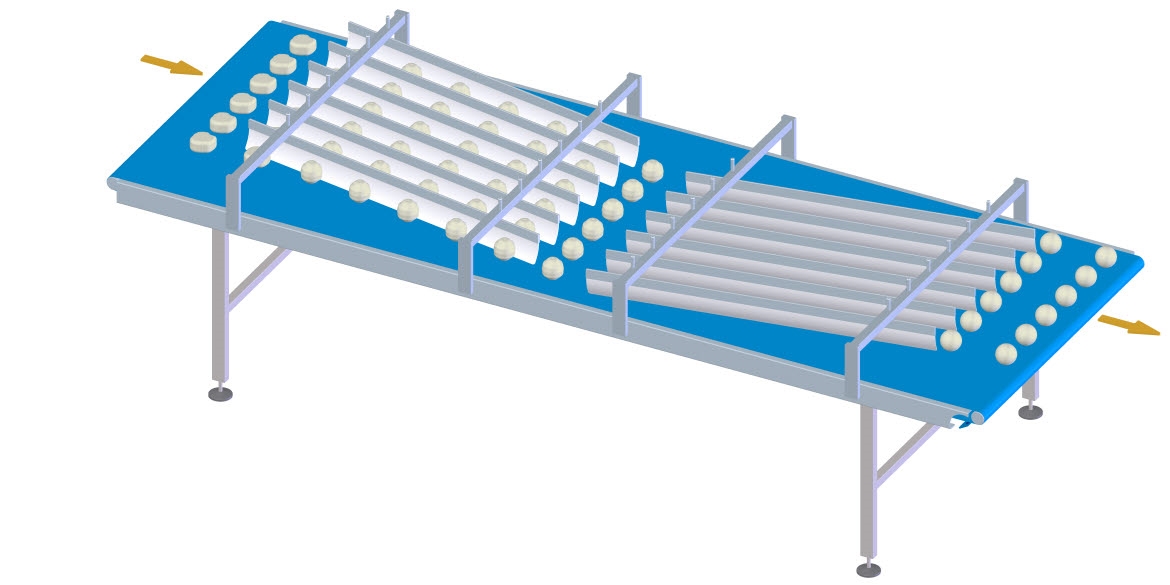

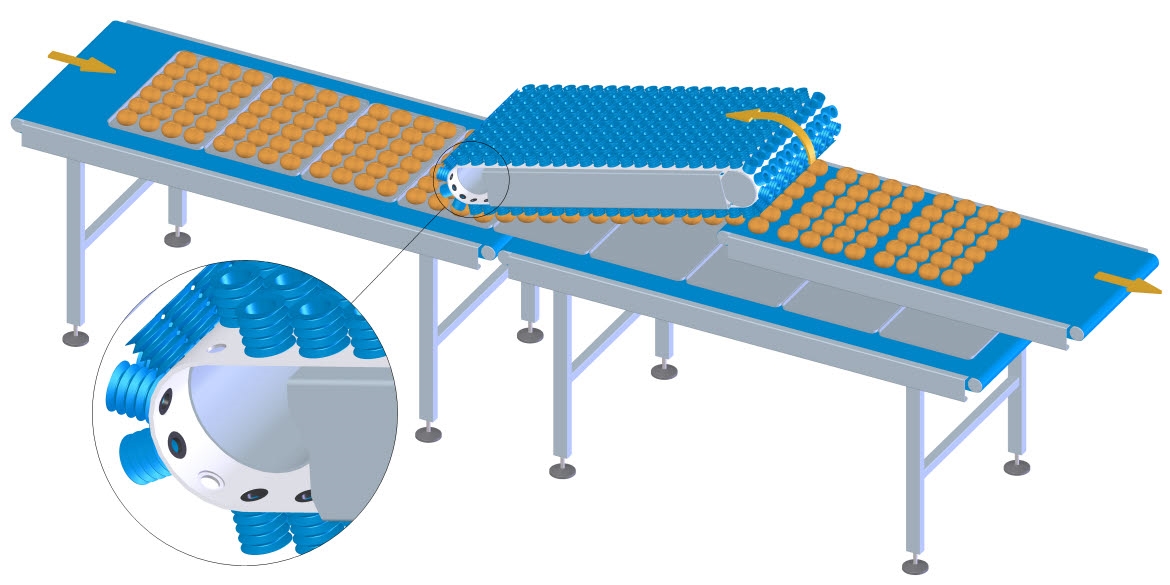

This is where it all starts! After the dough mixer, wet dough applications begin to determine size and shape to bakery products. We offer our extensive experience for your needs in dough handling with dedicated solutions in moulding, dividing and lamination.

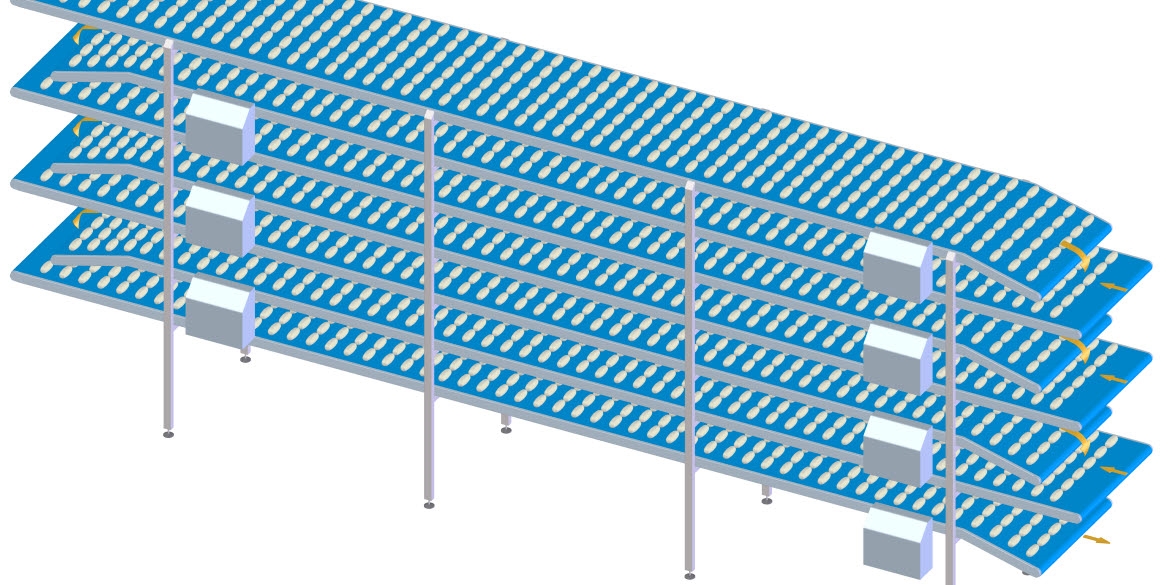

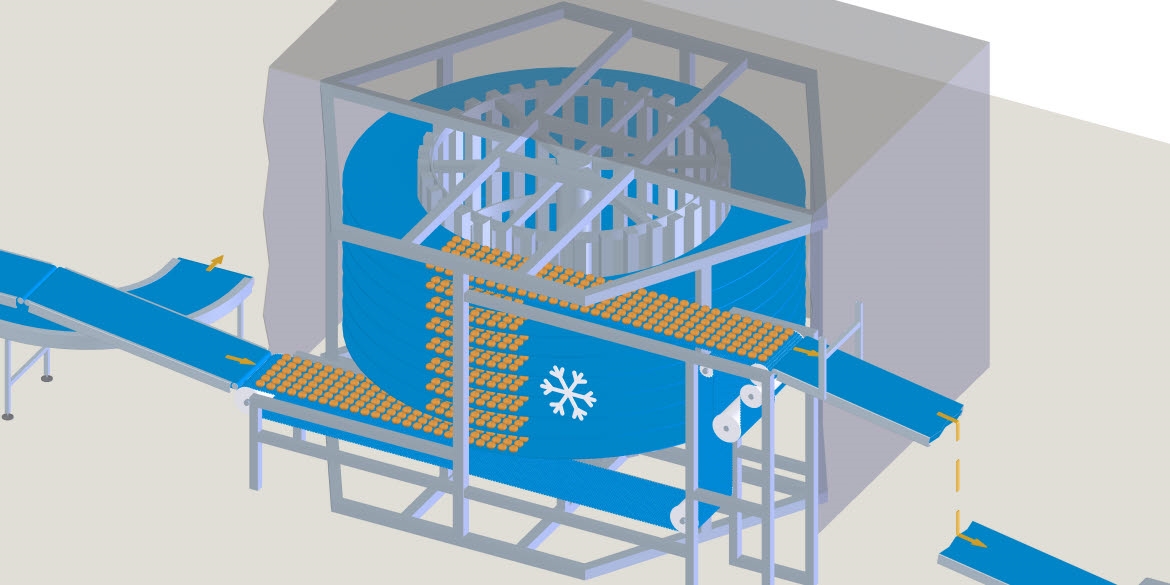

Perhaps the most delicate stage in the baking process, proofing is necessary for all leavened breads. Any dough stretching or vibration during this stage will damage both the appearance and the quality of the breads.

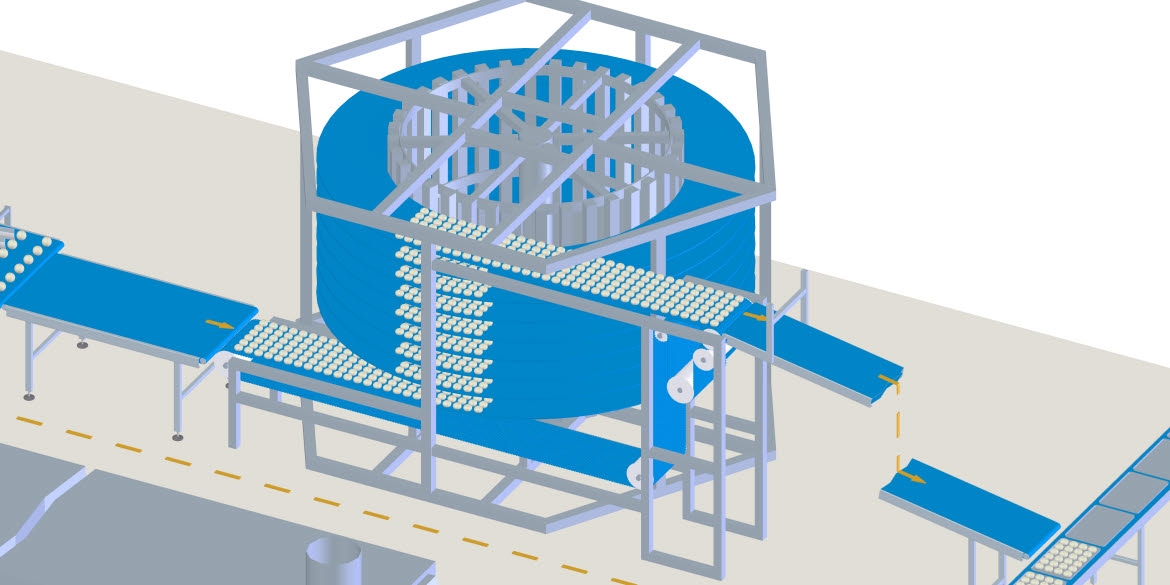

Due to the efficacy of their high-volume capacity combined with compact dimensions, spiral proofers are the preferred option for large industrial bakeries.

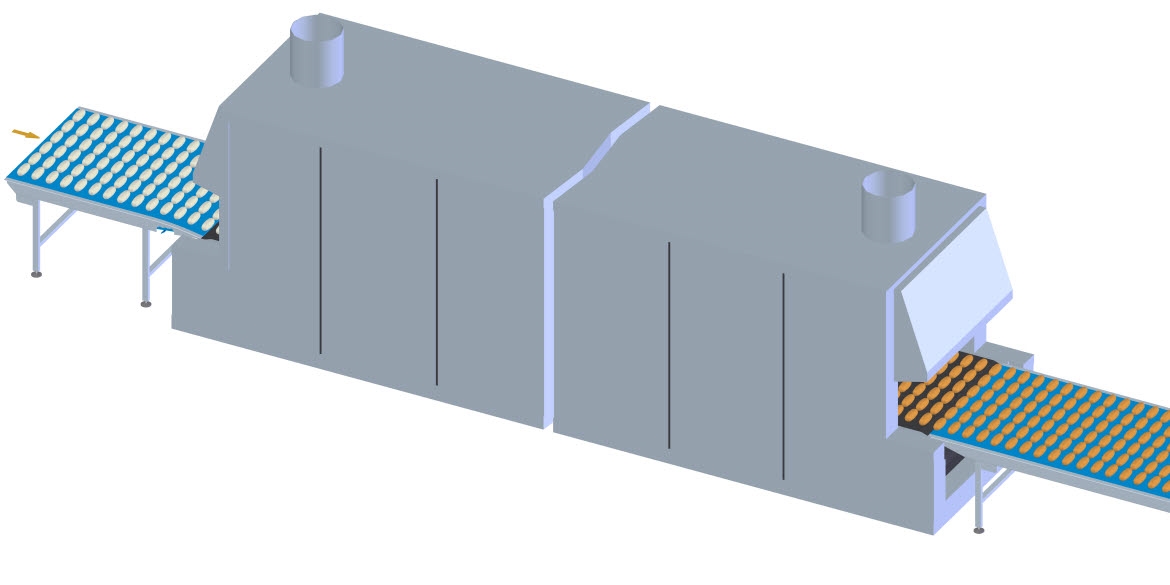

Bringing the dough to the oven to be baked and taking the bread away once it has been baked is a job for smooth-running belts that can handle the heat. Our range of solutions, developed from our long industry experience, include belts designed for direct contact with your dough as well as those made for conveying very heavy hot trays.

Ammeraal Beltech is familiar with all the challenges related to removing bread of different shapes and weights from baking trays.

Bread must be allowed to cool and the right amount of moisture must evaporate from the bread before the loaves are ready for slicing and packaging. Good air circulation during this period is critical.

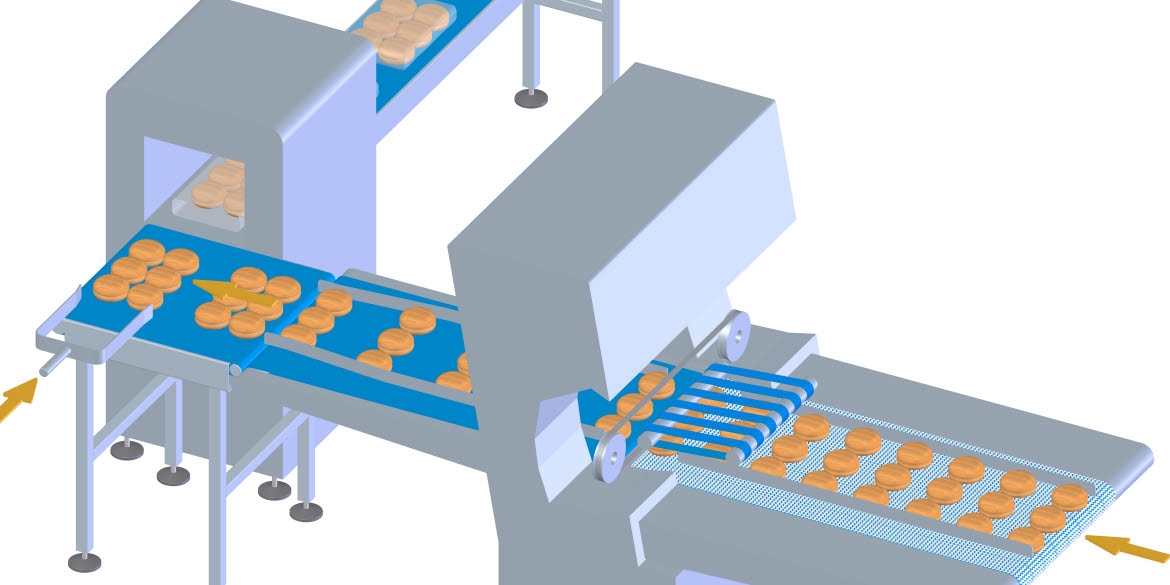

The last stage of production involves slicing, bagging, sealing and conveying the finished product to the end of the production line. This is also where the final inspection, including metal detection and weighing, takes place.

*Recommended Products are some examples of our solutions in a specific process. Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, colour and material combination for your specific requirements and local stock availability.

By continuing to browse our website you agree to our use of cookies and Privacy Policy. More information about cookies.