Global

International

Whether it's biscuits, cookies, snacks or other baked items, the Bakery Industry produces an irreplaceable part of our daily diet. This means that industrial bakery lines must keep moving, no matter what.

Explore using the drop-down menu or by clicking on the pointers

This infographic is used as a general indicative example only.

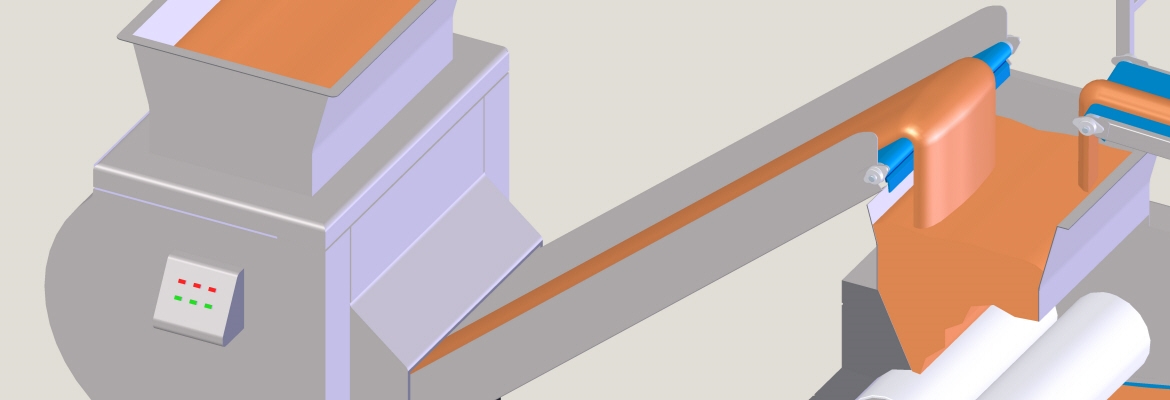

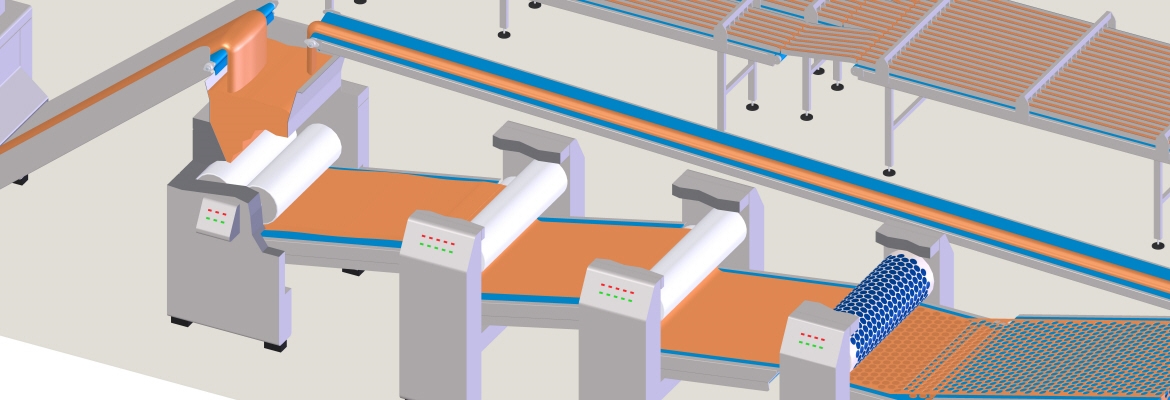

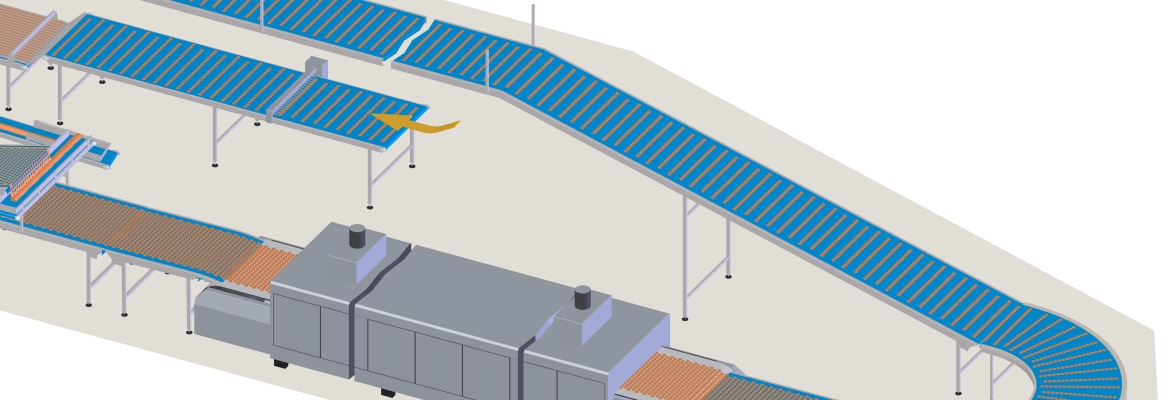

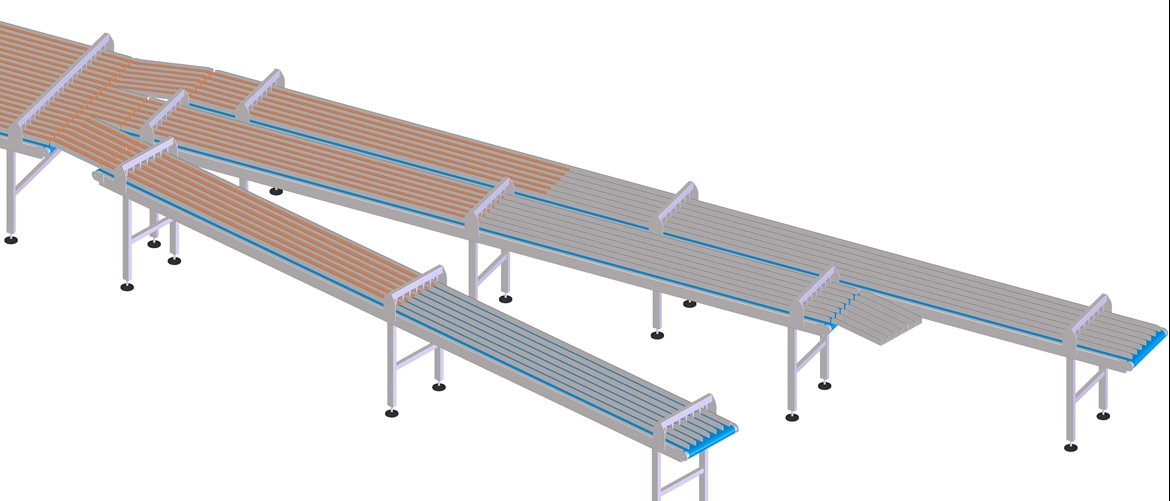

Actual factory and process configurations could vary, but our industry experts know them all. Above overview shows the factory lay-out with the rotary cutter. The rotary moulder and depositor are published separately. Please use the drop-down menu for more details.

This is where it all starts! Wet dough applications give the first shape to bakery products.

This process step, which ensures regular dough thickness, requires high-quality belt performance for a smooth transfer between the lamination stations.

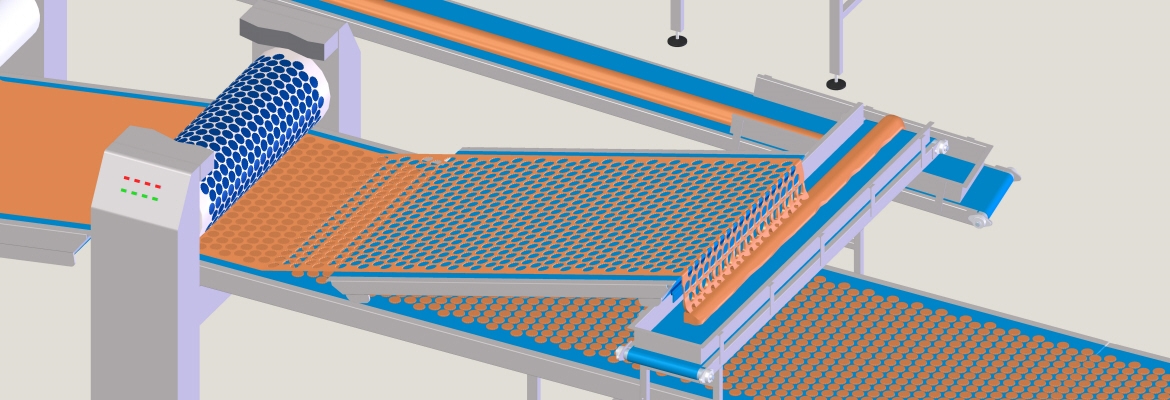

The quality of cookies depends in large part on using the appropriate belt with the proper grip and release properties during the cutting process, when the dough is delicate and thin.

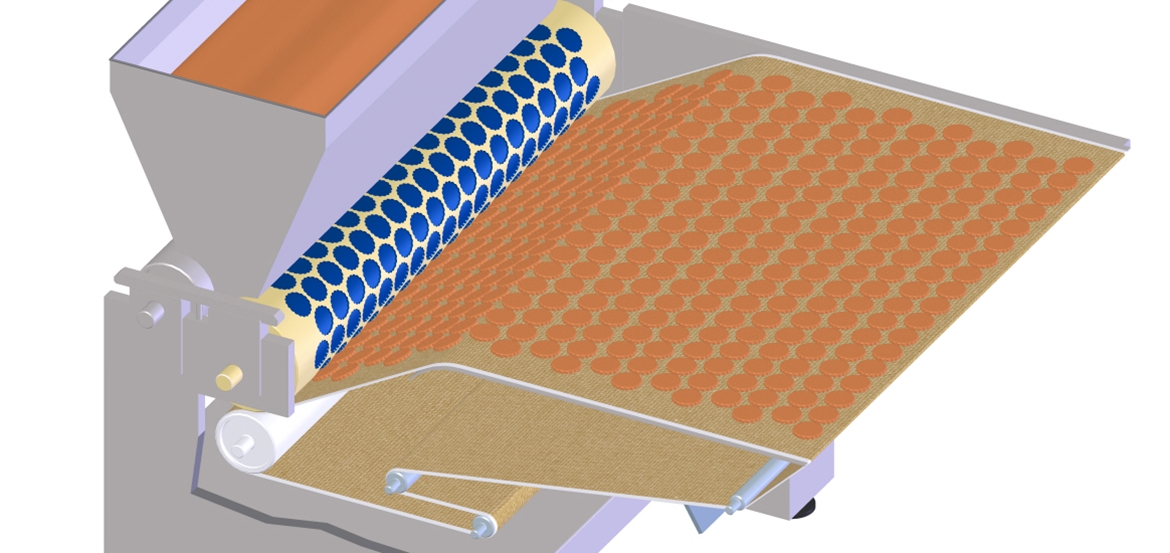

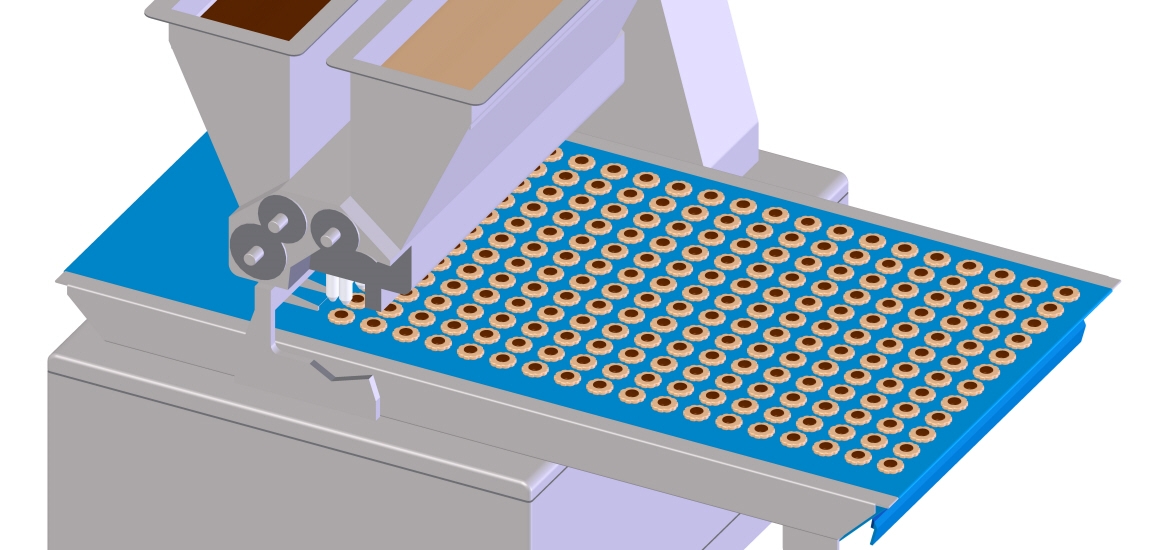

AmDough Endless Woven Belts offer unmatched quality in yarn material selection and weave design. The wide range of AmDough solutions guarantees the right rotary moulder belt for the right dough extraction.

Different dough ingredients are extruded from nozzles directly onto the belt, forming the cookies. Here, hygiene and resistance to oil and grease are very important.

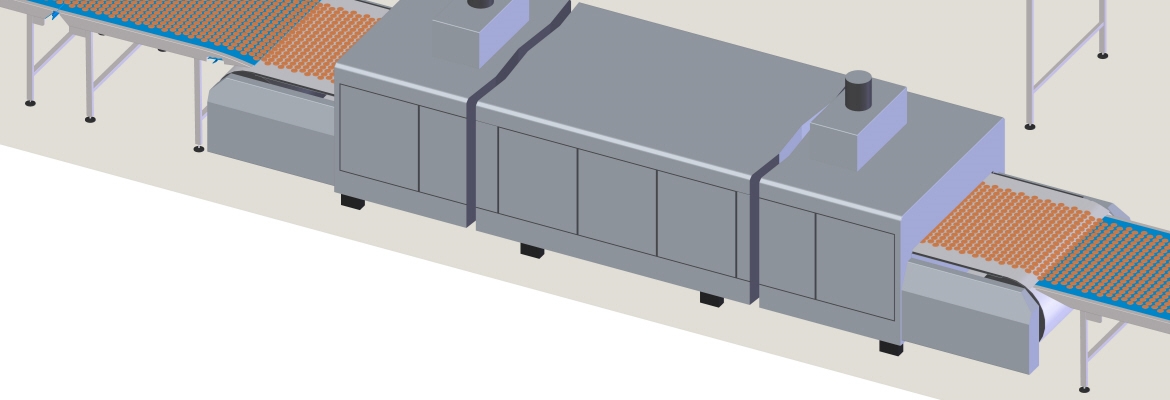

Releasing the thin dough as the products head into the oven and then taking the biscuits off the steel belt after the baking process are both very delicate steps in the manufacturing process. High temperatures, high-speeds and very small transfer points for reliable product positioning are all elements that require high-quality, high-performance belts.

Before transferring baked cookies from the oven to the wrapping machines, it is essential to ensure that the product is cool enough for handling.

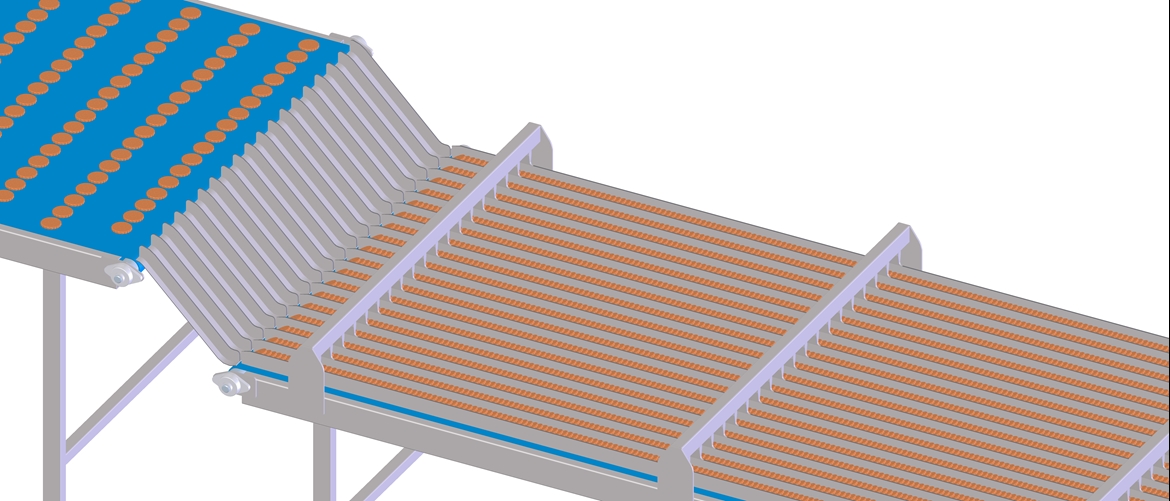

A very delicate stage in the production process, stacking is carried out by a set of conveyors (one of which runs at a lower speed than the other) gently overlapping and piling up the cookies along the metal rails for the horizontal flow-wrap packing equipment.

To ensure that the finished product ends up in just the right position for the flow-pack equipment, precise belt grip is essential. Accumulating or pulling fragile products requires either perforated high-grip belts or matt-finish belts to ensure low friction.

| Description | Article Code | Info | |

|---|---|---|---|

| Product group | |||

| SBRO572170 | Ropanol EM 6/2 00+00 (PU) light blue AS FG AM NL | Synthetic Belts | |

| SBRO572160 | Ropanol EM 6/2 00+00 (PU) transparent AS FG NL | Synthetic Belts | |

| SBRY577951 | Ropanyl EM 6/2 00+02 white M2 AS FG | Synthetic Belts | |

| SBRY578749 | Ropanyl ESM 5/2 00+015 white M1 FG | Synthetic Belts | |

*Recommended Products are some examples of our solutions in a specific process. Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, colour and material combination for your specific requirements and local stock availability.

By continuing to browse our website you agree to our use of cookies and Privacy Policy. More information about cookies.