Global

International

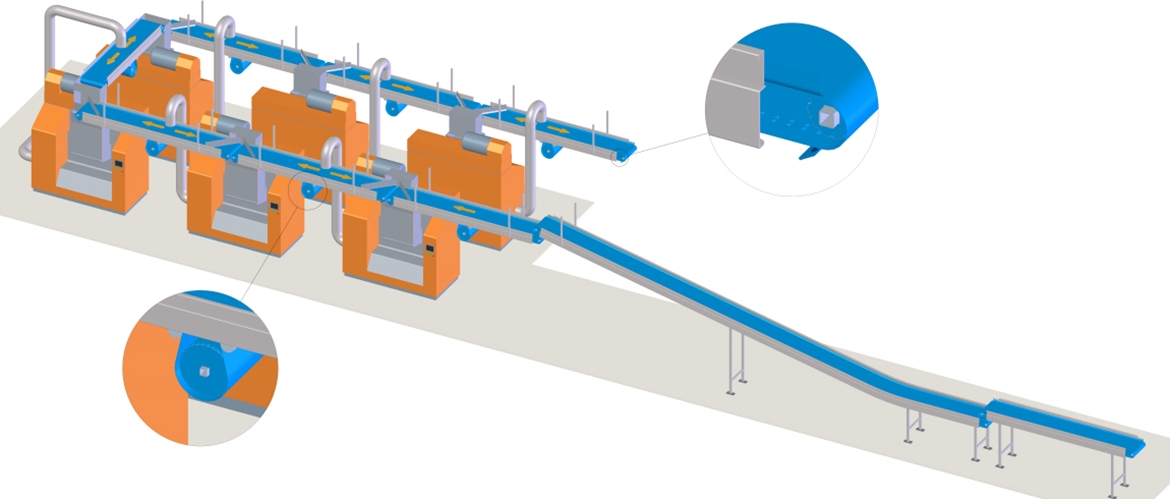

Confectionery can be difficult to deal with – products have a tendency to be sticky, tricky to cool and easy to damage. Our non-stick belts are designed to handle your sweets gently and hygienically, complying to all relevant Food Grade standards while performing with reliability and accuracy.

Explore using the drop-down menu or by clicking on the pointers

This infographic is used as a general indicative example only.

Actual factory and process configurations could vary, but our industry experts know them all.

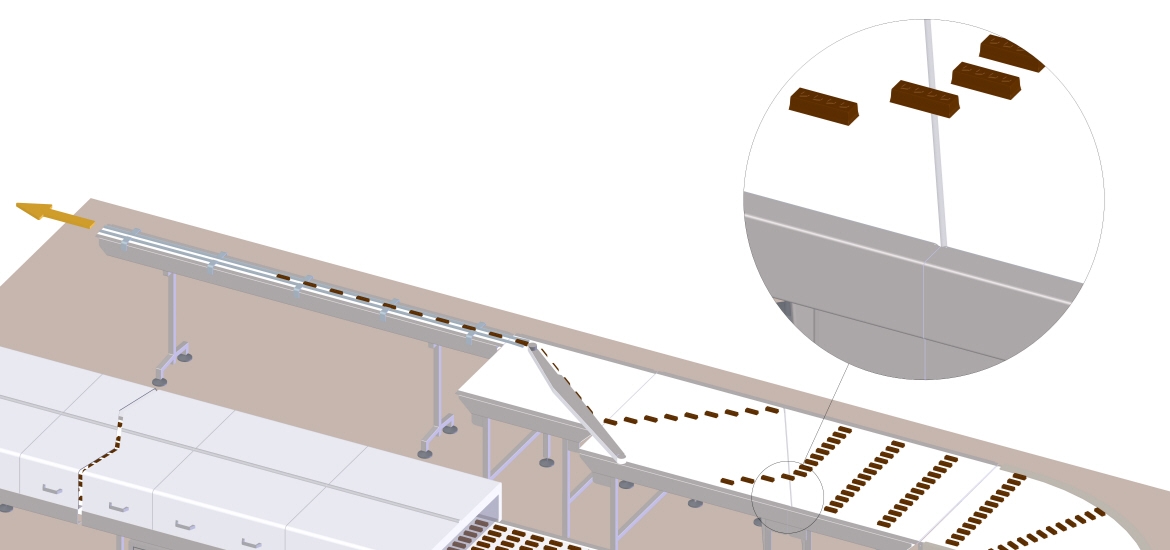

In cocoa processing, hygiene is of the utmost importance. There is a high risk of contamination at all times, and belts are particularly vulnerable.

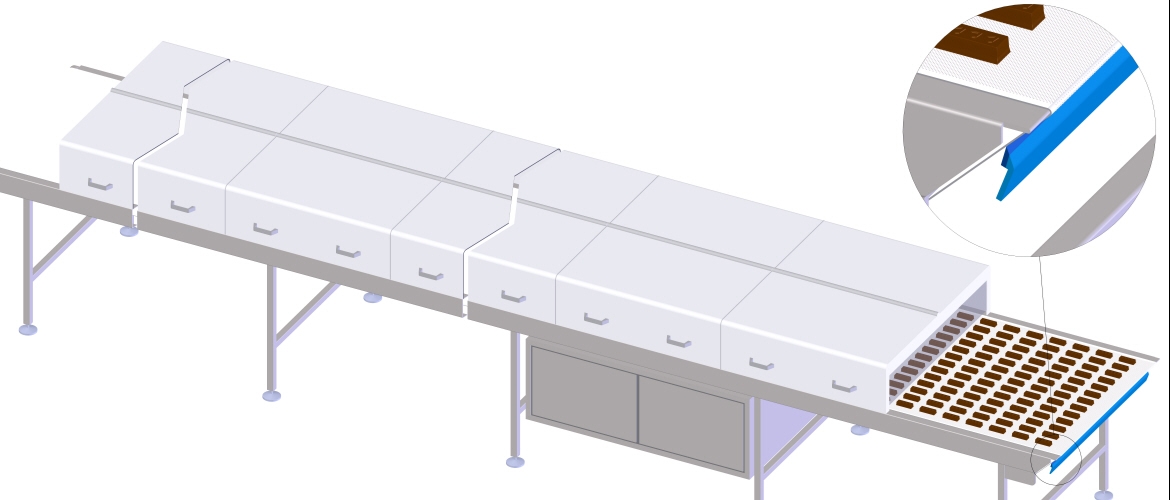

The "art of chocolate tempering" requires the use of the appropriate belt. A belt with a good thermal gradient will facilitate the difficult task of ensuring gentle cooling.

Wrapping and packaging confectionery products across a range of shapes, sizes and weights at high speeds needs a wide variety of belting solutions. Ammeraal Beltech offers you positive-drive and friction-drive belts with just the right friction required for every packaging need. Available solutions include Synthetic Belts, Engineered Belts, Modular Belts, Round Belts, Endless Woven Belts and Timing Belts.

*Recommended Products are some examples of our solutions in a specific process. Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, colour and material combination for your specific requirements and local stock availability.

By continuing to browse our website you agree to our use of cookies and Privacy Policy. More information about cookies.