Global

International

Year after year, FDA EU and Pyrolysis regulations become stricter. To help the industry conform, Ammeraal Beltech supplies high-quality halogen-free and nitrogen-free non-toxic belts offering outstanding production performance for greater process reliability and increased throughput.

Our wide range of tobacco belting solutions will significantly improve your overall process performance.

Explore using the drop-down menu or by clicking on the pointers

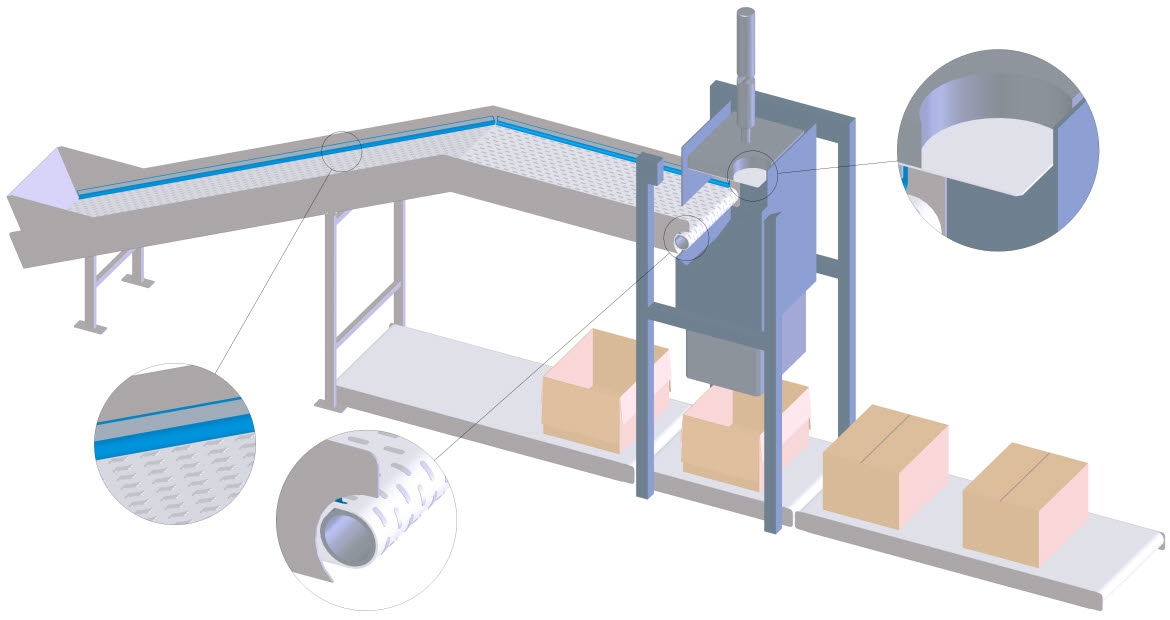

This infographic is used as a general indicative example only.

Actual factory and process configurations could vary, but our industry experts know them all.

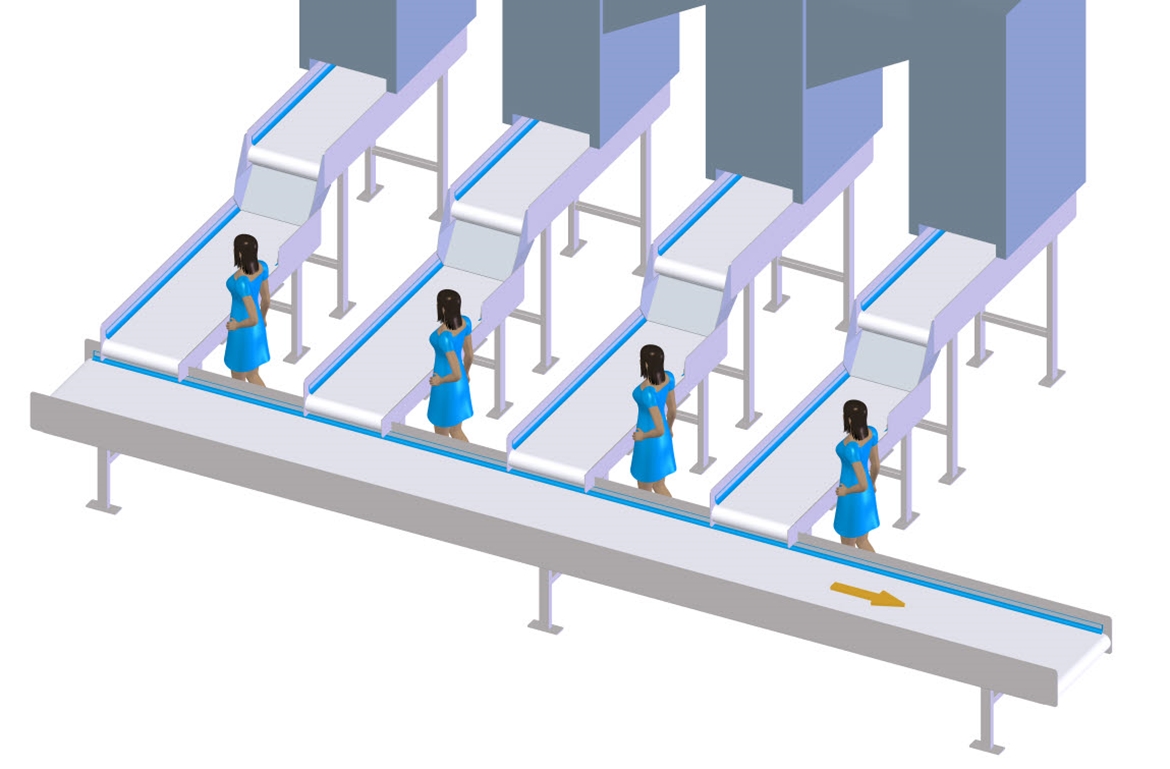

Dried leaves are brought in from the fields. The leaves are picked and sorted, all by hand. Conditions in the processing plants, which run round-the-clock, are difficult; the operating environment is very dusty.

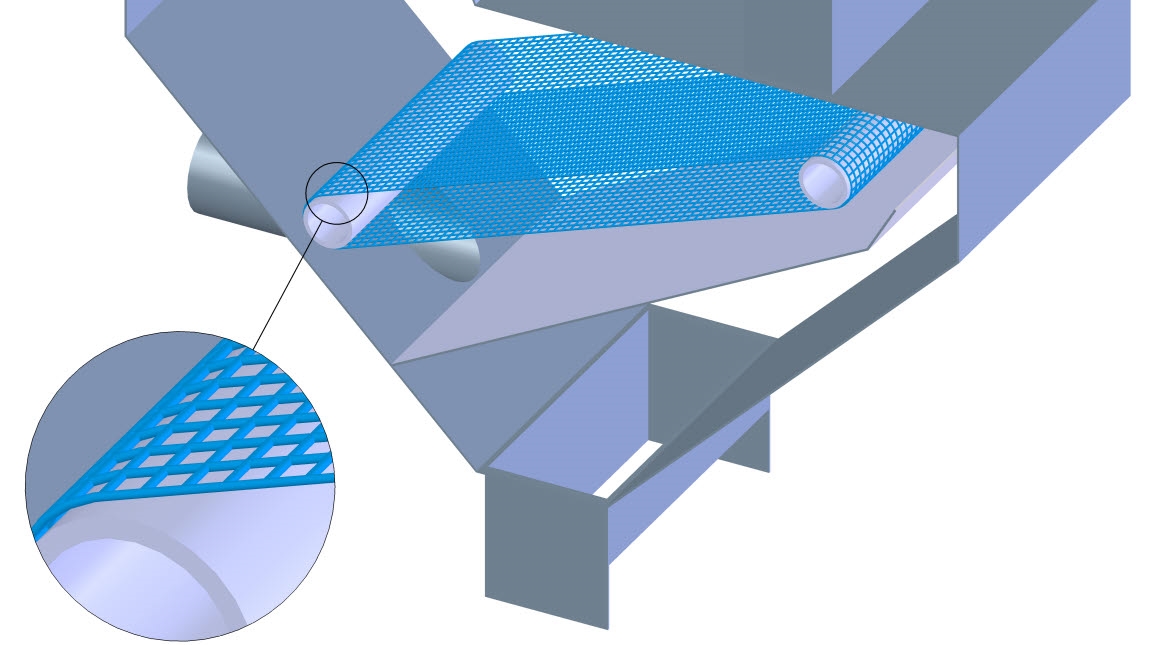

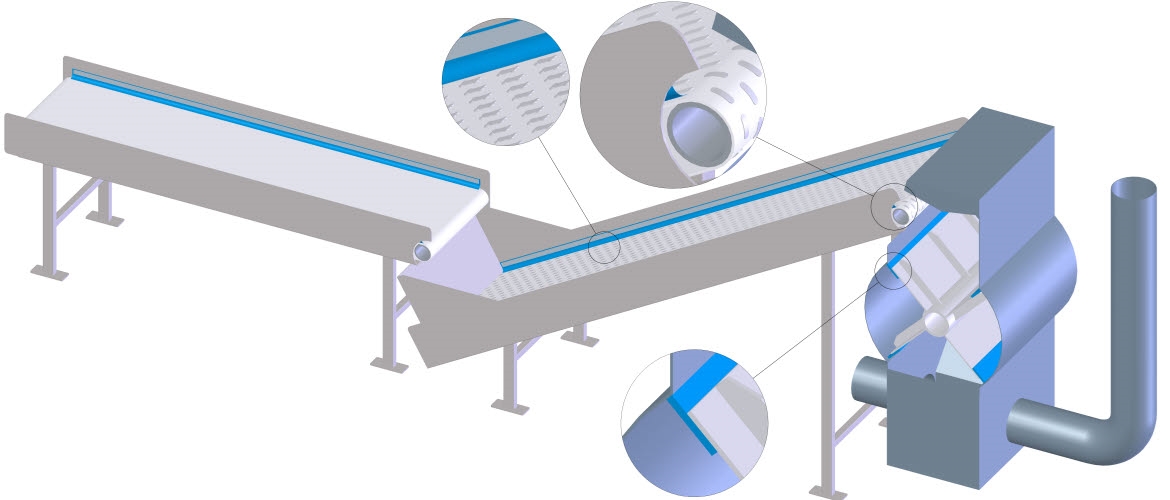

In this step, the lamina is separated from the stem and dust and small foreign particles are filtered out.

In this step, seals need to be airtight and belt material needs to be tobacco-proof, compressible and wear-resistant. The lightweight rubber fabric range with its natural rubber inner layer has all of these characteristics. The tumblers are fed by incline conveyors.

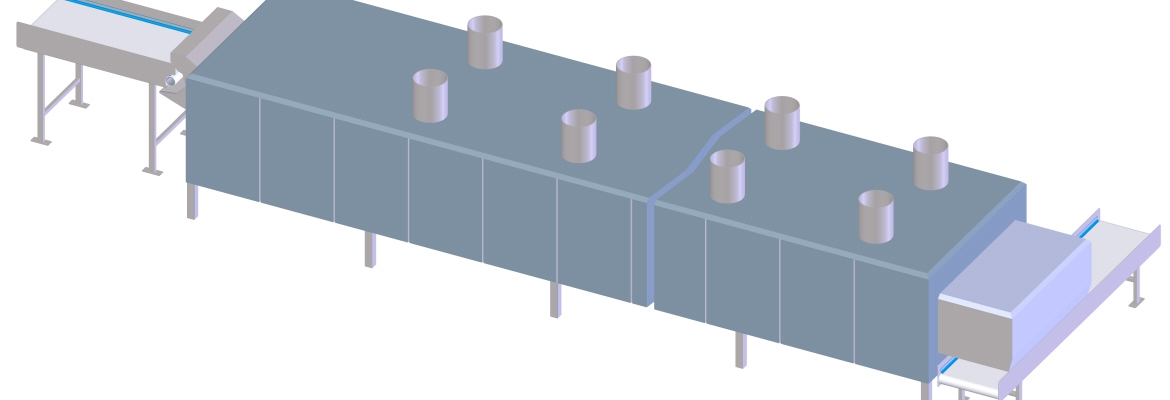

After threshing and tumbling, all the moisture must be removed from the leaves to make them suitable for transport.

Dry leaves and stems are packed separately in carton boxes to be shipped around the world. Hydraulic steel pushers are used to optimise box-filling.

*Recommended Products are some examples of our solutions in a specific process. Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, colour and material combination for your specific requirements and local stock availability.

By continuing to browse our website you agree to our use of cookies and Privacy Policy. More information about cookies.