Global

International

Manufacturing a tyre not only requires the latest technology, precision instruments and qualified people but also requires qualified suppliers.

Working together with our customers and leading research institutions, we have developed a full range of belting products for the Tyre Industry.

With the unique product portfolio of fabric based Process and Conveyor Belts, as well as uni Modular Belts, Ammeraal Beltech provides the best technical belting solutions for all tyre manufacturing processes.

Explore using the drop-down menu or by clicking on the pointers

This infographic is used as a general indicative example only.

Actual factory and process configurations could vary, but our industry experts know them all.

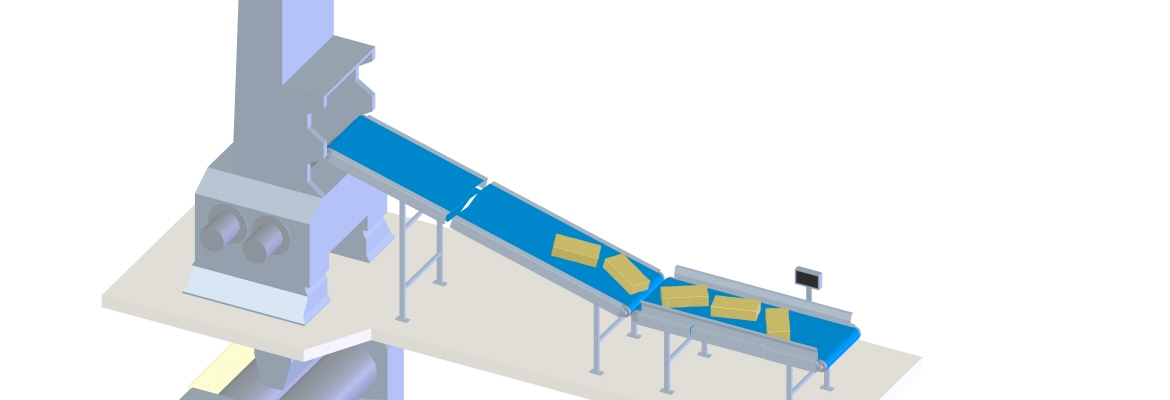

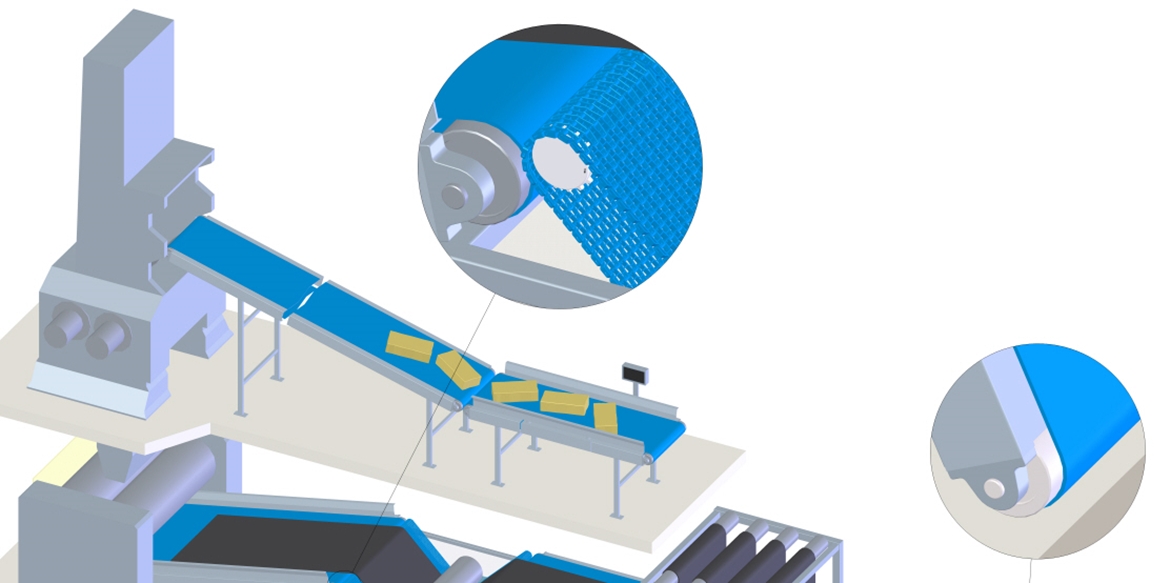

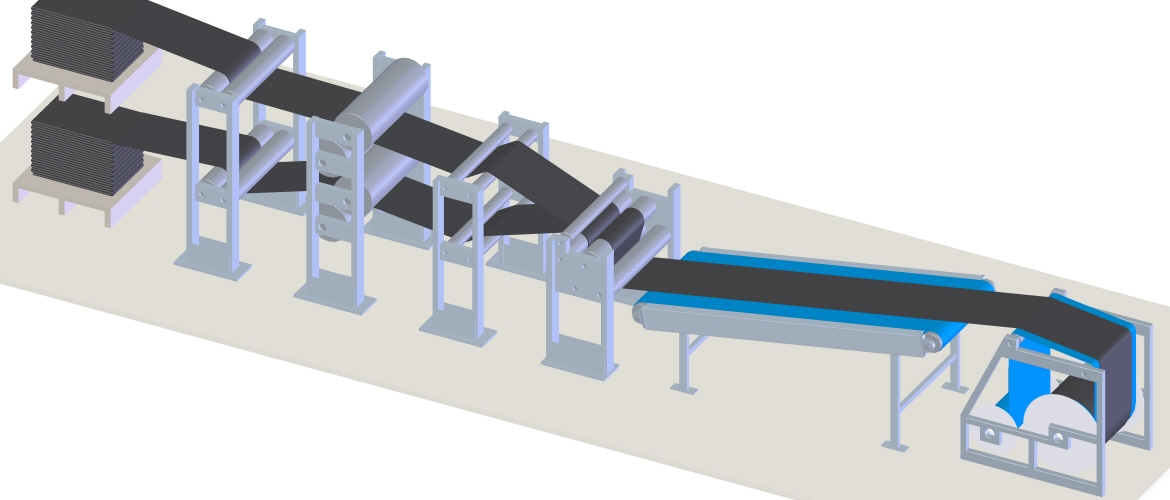

Components per tyre type recipe needs to be weighed and transported into the mixer.

Raw materials are mixed into a homogeneous rubber compound. There are two different mixing types in the market:

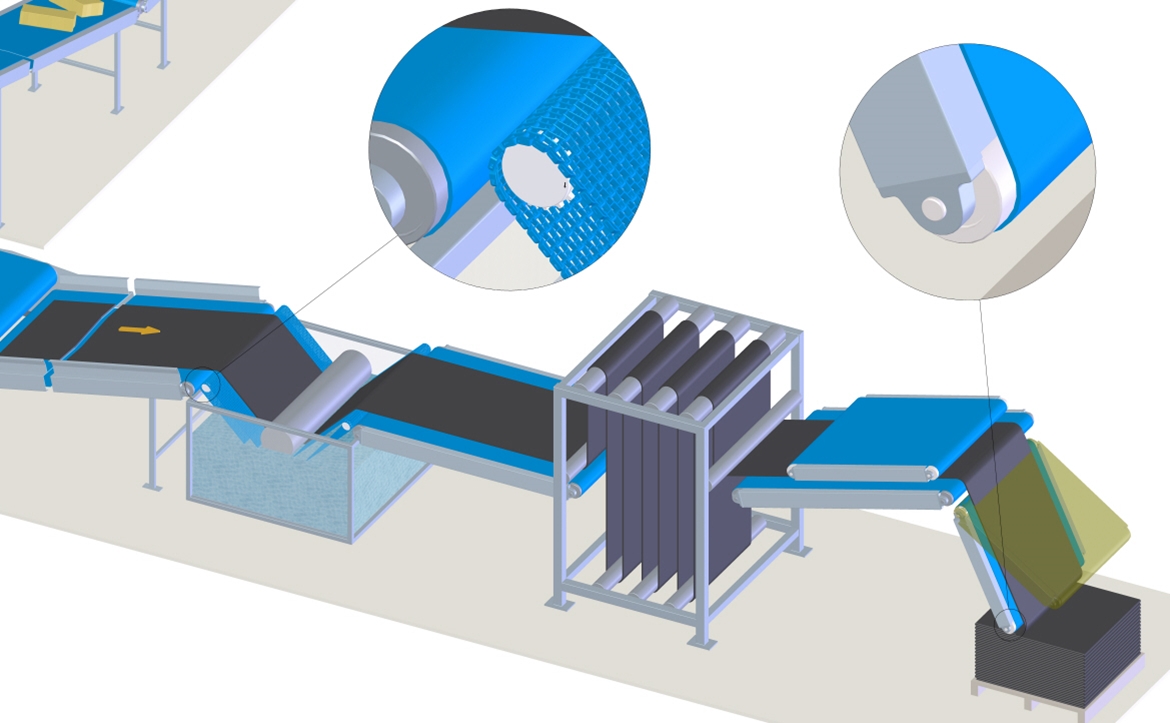

The mixed rubber compound needs to be stored on pallets before the next manufacturing steps are coming. To avoid that the rubber sticks together it is dipped in a soapy water bath, cooled and stored with a wig wag unit on pallets.

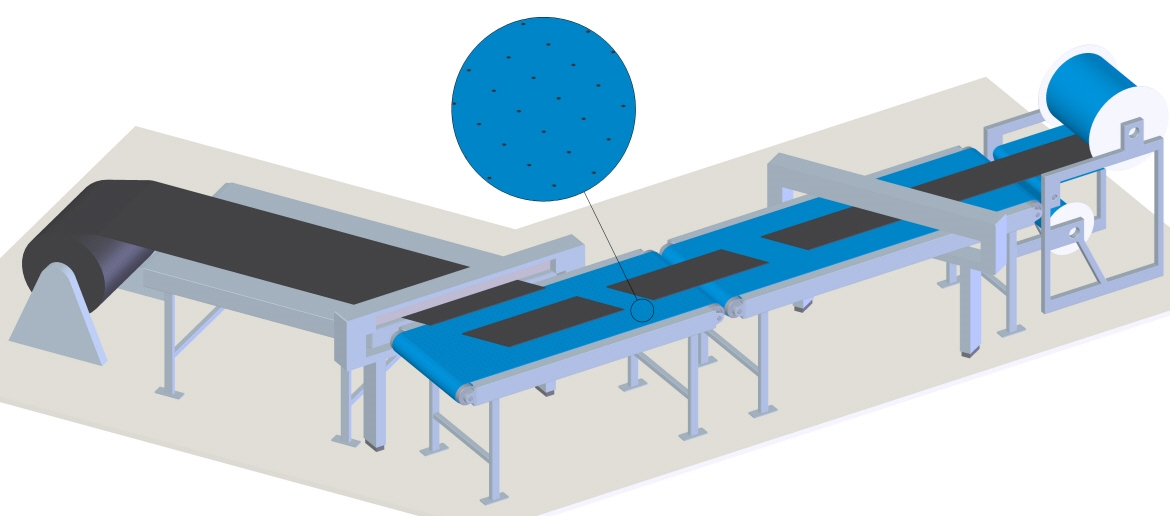

This is a mechanical process by which rubber is pressed into textiles (cloth, fabric) or steel cords to form composite sheets. Calendered textiles are used for casing, cap plies and chafers. Calendered steel cord is used for belts.

Finished steel cord (for Breaker Belt, Body Ply) and textile cord (Body Ply, Strip) is cut into appropriate sizes, shapes, and angles depending on the desired contour of the tyre.

There are three different cutting methods:

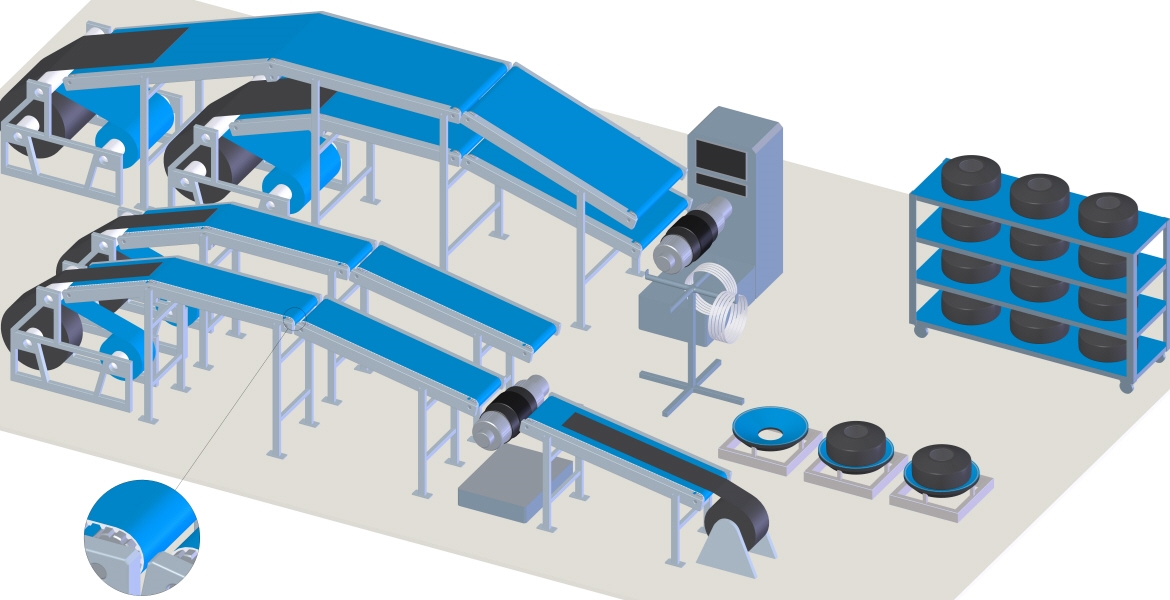

Extrusion is the process by which heated rubber (80 °C - 120 °C) is pushed, under high-pressure, through an extruder head, to pre-shape the rubber. The next step is the cooling line where the rubber (tread, sidewall) is cooled and the dimensions are stabilised. The new semi products need to be stored before the next production step (TBM) and this is done via winding units (liner) or other storage systems.

This is a mechanical process by which multiple rubber layers are pressed in a multi-roll calender towards one homogeneous rubber layer. An alternative is rollerhead equipment. The rubber compound plasticised in the extruder is conveyed via a wide extrusion die directly into the roll nip of a two-roll calender.

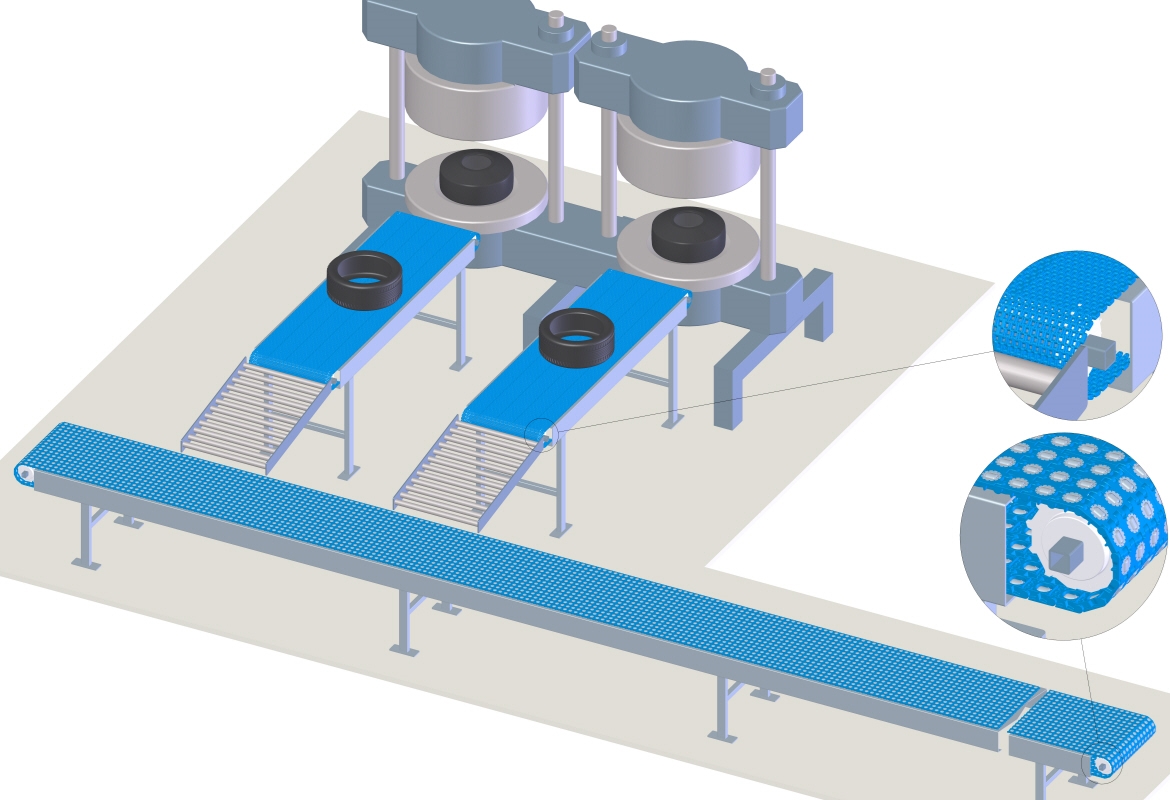

The first step in final finishing involves the tyre-building machine (TBM), with over 40 components that work to form the green tyre.

Curing is the process of applying pressure to the green tyre in a mould in order to give it its final shape, and applying heat energy to stimulate the chemical reaction between the rubber and other materials.

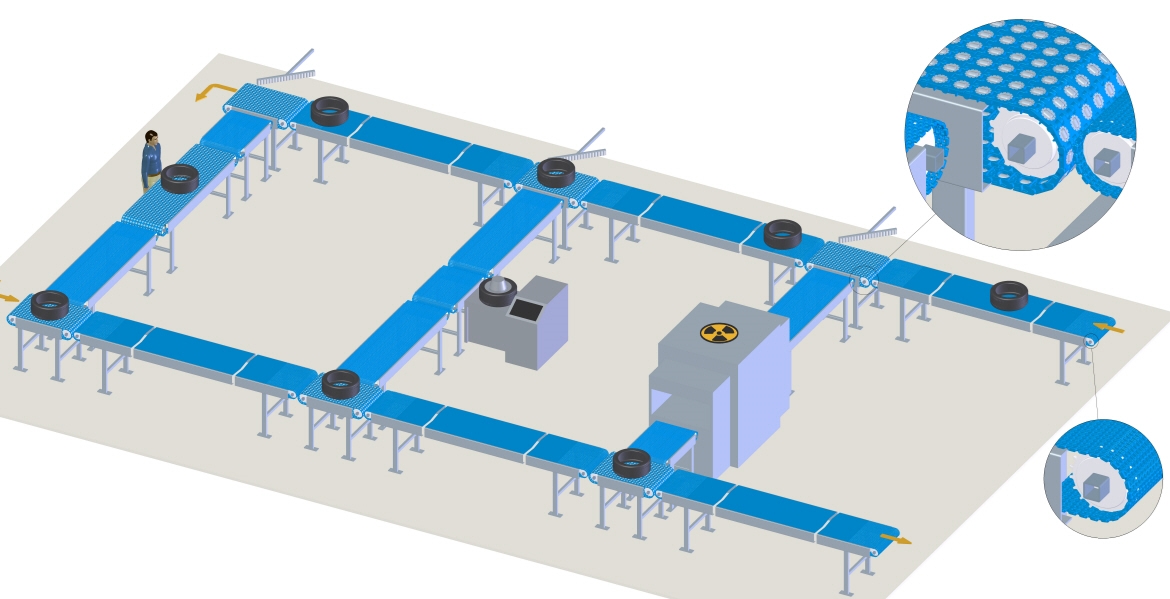

After the tyres are cured in the press, they are often cooled down on a conveyor belt and then transported to the trench line (collector line).

After the curing presses, the tyres are cooled before going for inspection and collecting. Finished tyres need to be handled with care, so transfer roller belts are used for conveying.

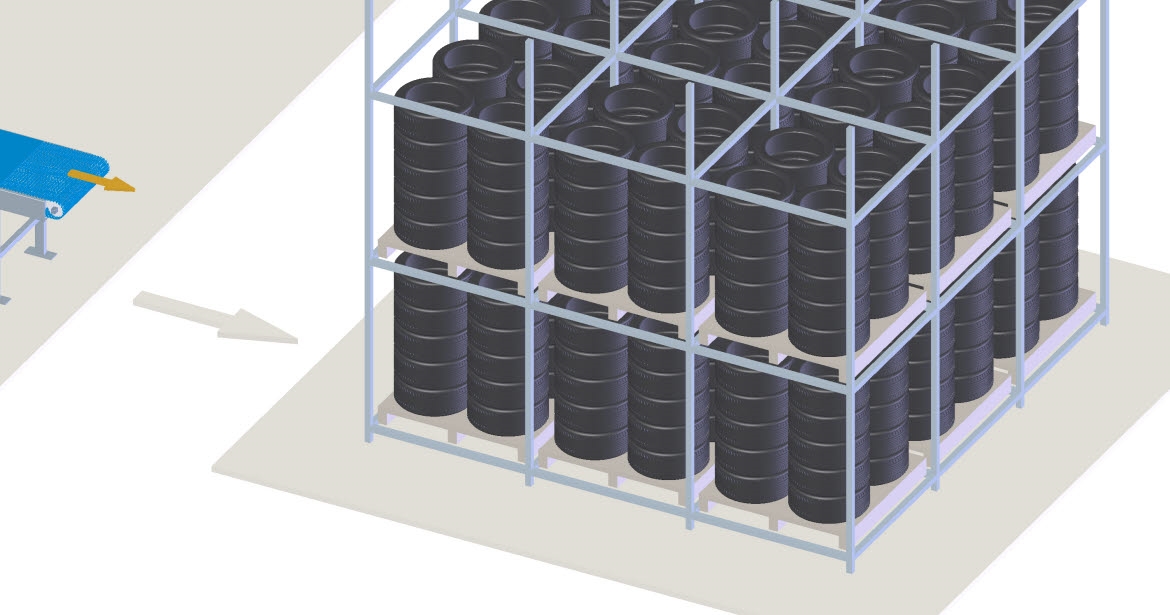

Finished tyres need to be stored (short term) before they are transported to the hubs of the sales channels.

This storage has a demand of intralogistics where conveyor belts are often used.

To quickly load and unload trucks it is common to use telescopic loading systems.

*Recommended Products are some examples of our solutions in a specific process. Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, colour and material combination for your specific requirements and local stock availability.

By continuing to browse our website you agree to our use of cookies and Privacy Policy. More information about cookies.