Global

International

The combination of wood fibers and resins, together with high temperatures and high pressure applications, presents serious challenges for the conveyor belts used by panel board manufacturers.

The work environments in this industry require belts that are durable, reliable and easy to clean and service. That’s why leading Original Equipment Manufacturers and End Users choose our belting solutions for reliable and safe processing performance.

We are able to supply high performance solutions for:

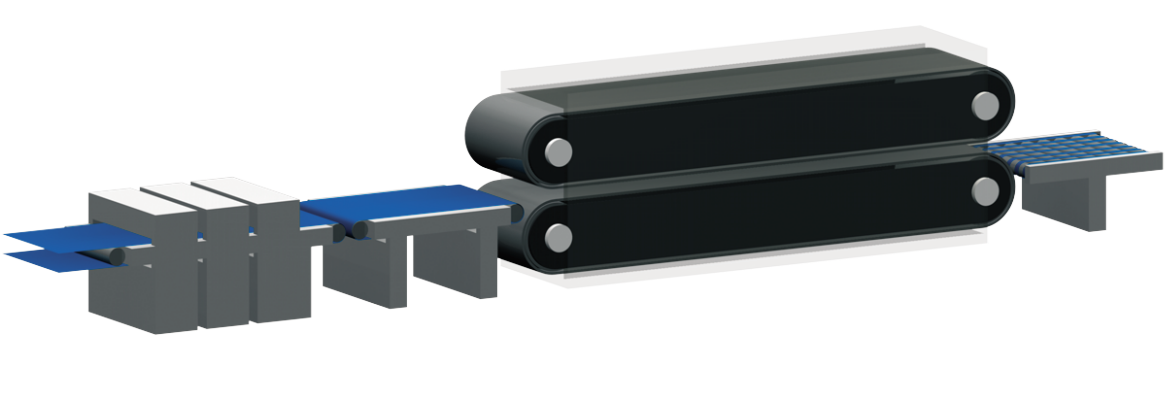

Our solutions are innovative for all production processes. For further details see the image below and choose your requested application!

Explore using the drop-down menu

This infographic is used as a general indicative example only.

Actual factory and process configurations could vary, but our industry experts know them all.

Rotary dryers are the most commonly used dryer type in the particle board industry. The moisture content of the particles entering the dryers may be as high as 50% for wet particles. Drying reduces the moisture content to 2%-8%.

After the mega dryers, wood particles are first stored in the dry chip silo and then weighed. Belts for these applications should be ATEX-certified and have anti-static and flame-retardant properties.

Particles from the weighing belt are distributed into mat-forming machines, where they are prepared before they are layered onto the forming belt.

The forming line belt, is the core belt in the particle board process, running straight through to where the board is transferred into the press. MDF, PB wood fibers and OSB strands all go through the forming line.

The fragile fiber mat must first pass through a pre-press system where it is compressed between the forming belt and the de-airing belt. The de-airing belt helps press air out of the mat.

After the pre-press station, the fiber mat is transported to the press stations, cut into panels and fed into the multi-opening press. A gigantic cylinder presses the boards into their final shape and density.

Steam Injection is a special infeed system that uses a top and bottom belt to inject steam into the fiber mat, speeding up the production process by 10-30%.

After the boards have been pressed, they are transported to a huge cooling wheel, also known as the star winder, to be cooled down (the air cools them) and turned over.

The finished boards are now ready to be stored, and need to be moved to their storage location.

*Recommended Products are some examples of our solutions in a specific process. Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, colour and material combination for your specific requirements and local stock availability.

By continuing to browse our website you agree to our use of cookies and Privacy Policy. More information about cookies.