Global

International

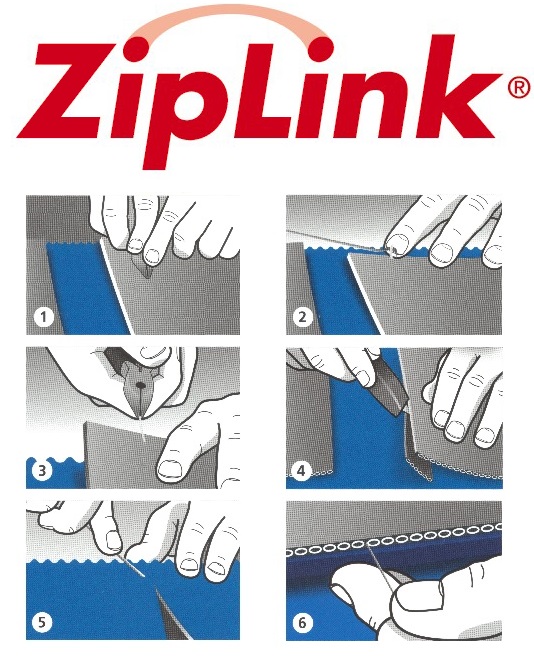

The way ZipLink® is built removes any potential weak spots, being more durable than seamed or fused belts. Even after repair, the belt remains as strong as before.

ZipLink® avoids fasteners that could damage the product, making our customers safer and independent of external services for the on-site splicing. What is more, one ZipLink® roll can cover all positions of the same width, helping with stock optimisation.

The ZipLink® range was created to meet the needs of multiple applications in many segments, such as Corrugated board, Wood, Insulation, Logistics, Tyre, Ceramics, and more. All in all, ZipLink® range provides a reliable, effective, and adaptable solution for belting applications.