Global

International

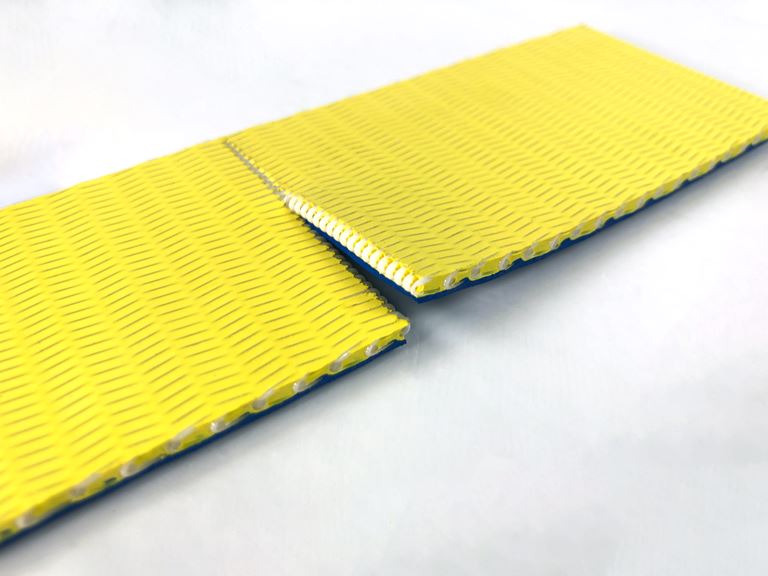

ZipLink® is the ultimate solution to drop expensive machine downtime and improve performance and quality output. In every industry machine downtime is public enemy number 1. ZipLink® is the solution! ZipLink® Belts can be installed in minutes on the large majority of equipment without the need of specialized labor or external service. This resulting in major savings and extra production time!

ZipLink® Belts have virtually no splice area, meaning no weaker point in the whole belt. This resulting in the chance of production speed increase. More output!

Our ZipLink® Belts have no extra thickness spots, or metal part to damage machineries and goods. Better quality of products!

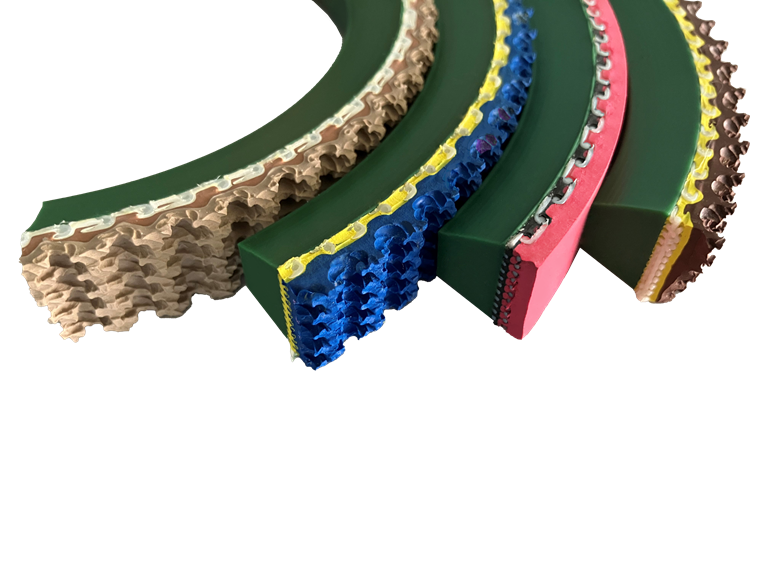

ZipLink® range is a highly practical and cost-effective belting solution for various industries and purposes. Its unique mesh structure allows for convenient splicing without special tools, reducing downtime and increasing productivity. What is more, it can be customised with a variety of top-cover materials.

Read more

During their conveying process, the movement of the ceramic tiles on the belt can quickly deteriorate its coating, leading to continuous repairs and maintenance expenses.

Non-slip, high-abrasion and chemical resistant, ZipGuide belts are designed to keep your ceramic tiles safe at every stage of your production process.

Read moreMeet Zipflex, the latest innovation from Ammeraal Beltech, designed to transform the way you manage your conveyor systems.

This game-changing belt link insert simplifies belt swapping, reduces maintenance costs.

Read more