Global

International

Semi-finished belts can be customised to exact requirements.

In our fabrication centres, belts are trimmed to size for length and width. Belts can be made endless by means of various splicing methods and can be engineered with holes and grooves.

They can also be fitted with accessories such as carriers, ropes, cleats and sidewalls.

Covering materials determine a belt’s unique set of properties, such as friction, flexibility; wear resistance and oil and fat resistance.

Ammeraal Beltech can apply an extra cover to almost any base belt, whether it is a standard belt, a high-performance flat belt or a timing belt. We offer an extensive range of covering materials, including rubbers, PVC, polyurethane, cellular materials and other special materials.

For more information about our range of covering materials see: Covering Materials.

Our belts can be made endless by various methods:

Examples of machining are:

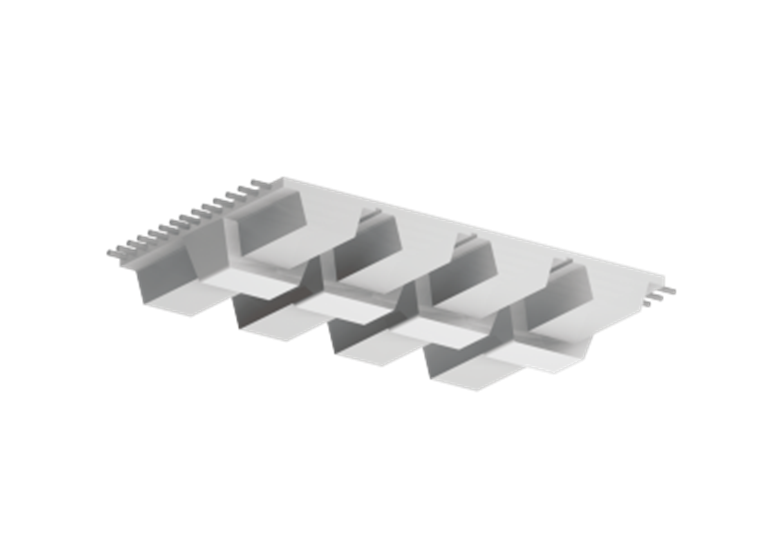

Cleats are a popular accessory. Different types are available.

Welding of cleats to belt can be done with infrared welding, friction welding or contact heated tool welding. Cleats are available with metal teeth to enable mechanical attachment to the belt.

In the case of PU belts, welded-on profiles / cleats can be made from the same material as the body of the belt.

Fabricated v-guides are available for timing belts: PU Linear, PU Torque and PU Moulded Belts.

V-guides can be fit to any belt type in any width and length combination.

The guides can be glued on and can also be added onto the back side of the belt.

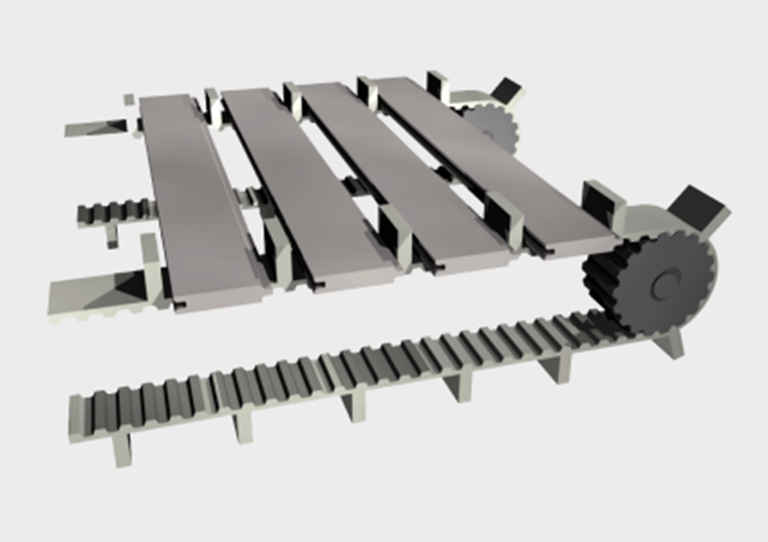

Pulleys for timing belt applications can be selected from the standard range or they can be manufactured according to specific drawings and requirements. Standard range consists of pulleys for all common timing belts with standard widths, diameters and construction.

Materials: