Global

International

Food safety is of paramount importance to protect consumers and their health. As Ammeraal Beltech, we are strongly devoted to this concept and take up measures to continuously develop solutions improving the level of hygiene and safety at your premises. We accept no compromises in food safety.

What is Food Safety?

Food safety means handling, processing, and storing food in such a way to prevent contamination or poisoning. All responsible food producers have in mind the health and safety of their consumers. Before foodstuffs land on store shelves a lot can be done to ensure they are free from life-threatening contaminations and bacteria.

Why Food Safety Matters

Food safety standards protect consumers against contaminations and foodborne illnesses. However, following them is important not only for the sake of end users but also for your business. We understand how costly product recalls and destructive downtimes can be. Companies that neglect food safety norms are subject to serious prosecutions, lawsuits, and even bankruptcy. Not to mention damage to their reputation, financial losses, and compensation claims. Being a company devoted to the food safety concept means building a strong brand image of a responsible leader truly caring for the wellbeing of customers. At Ammeraal Beltech, you may find a full range of products to help you enhance the hygiene level of your production line.

Belt Selection & Food Safety

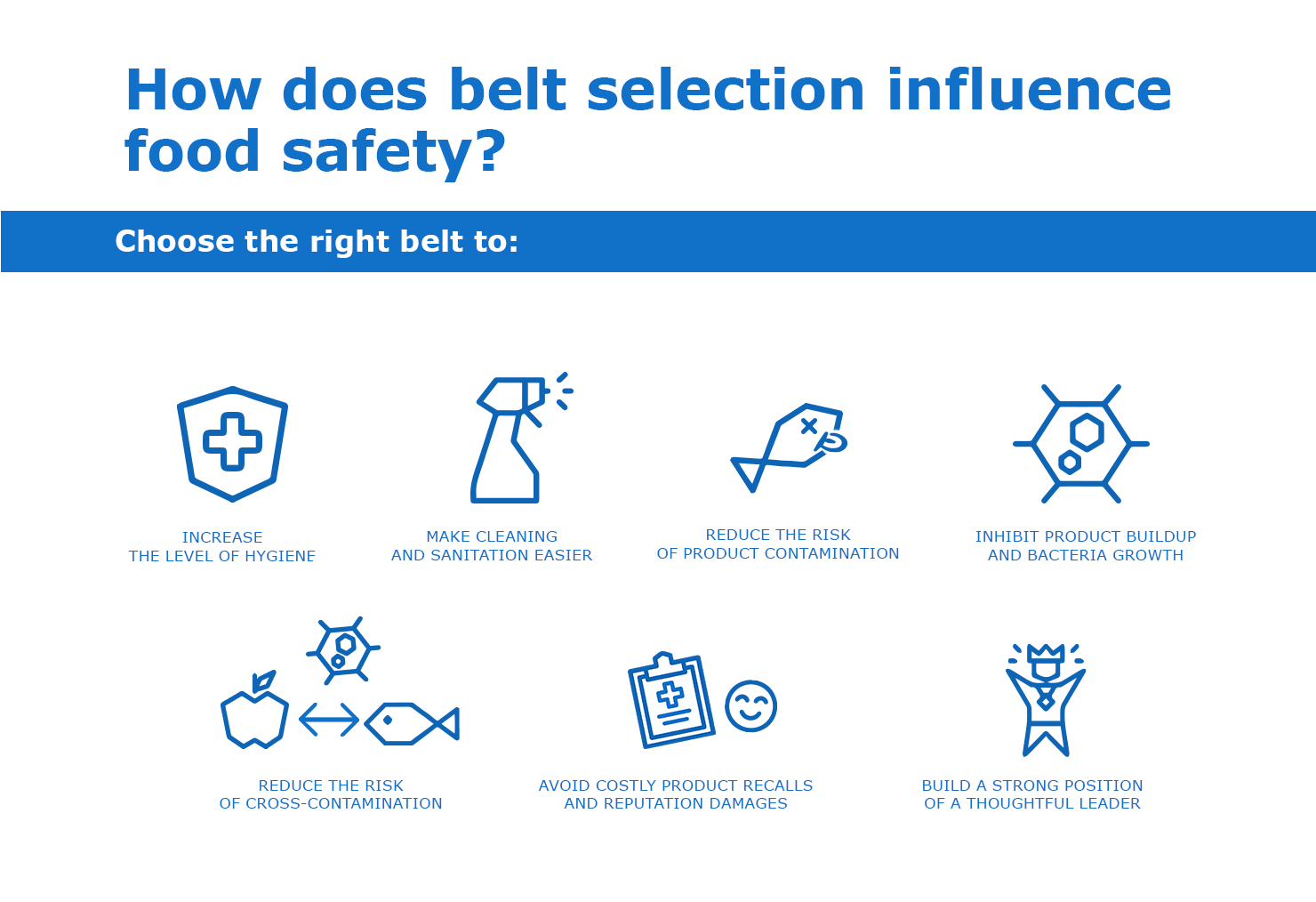

Selecting the correct belt is a critical component in a total plant hygiene and sanitation strategy. Choosing the right solution translates into higher food safety standards.

Blue belts are commonly used to improve the security of food processes. The colour is rarely seen in food items and thus foreign particles can be immediately spotted in the goods conveyed. What is more, the blue colour exposes food residues and makes it easier to keep the belt clean.

Technological advancements have brought even more revolutionary solutions. Now it is possible to invest in belts whose particles can be identified by metal detectors. This breakthrough significantly reduces the risk of pollution from broken belt particles. The technology is used for example in Dectyl. Other innovations involve the use of silver ions inhibiting the growth of bacteria as in the case of Ammeraal Beltech AntiMicrobial belts.

Some belts are easier to keep clean than others due to their design. A thoughtfully constructed belt requires less time to be cleaned and sanitised. Its features contribute to reducing the risk of cross-contamination and counteract product buildup. A well-engineered solution for food safety demonstrates strong resistance to chemicals and non-stick properties. Excellent release features ensure cleaner and extra-smooth transfers. Non-wicking qualities prevent the absorption of fluids and oils, enhancing hygiene and inhibiting the growth of pathogenic microorganisms.

The durability of the belt is of significance, too. Belts can develop cracks, either by extensive exploitation or contact with knives and other sharp materials. The food particles get into those cracks, grooves, and cavities, paving the way for harmful bacteria to grow and poison the products. Consequently, it is better to invest in durable solutions in which the above-mentioned problems do not occur from the very beginning. Look for crack-free food belts like Nonex and Ropanyl, which are characterised by excellent sanitation standards and a long lifespan.

As you may see, choosing the belt wisely influences the health of your customers but also secures your company against costly recalls and reputation damages. With professional solutions offered by Ammeraal Beltech, a member of AMMEGA Group, you establish your position of a thoughtful leader and show care for your clients’ welfare.

Belts for improved safety

Ammeraal Beltech offers a full range of products and accessories to make your food production safer. All our food-grade belts comply with worldwide safety standards such as the American FDA and the European USDA. Below you can find the list of our top solutions for improved food safety.

Watch the food safety product portfolio!

We’ve compiled all our food safety product portfolio into a playlist. Watch our solutions in action!

Contact us to improve your food safety level!

Ammeraal Beltech is a proud member of the AMMEGA Group. Combining the strengths of all brands within the family, we make your business move. Years of expertise and know-how enable us to take care of your food safety needs at the highest level. Contact us to improve food safety at your production line!