Global

International

Tobacco and Ammeraal Beltech share a long history. We have worked with the leading tobacco processing equipment manufacturers and with the world’s most important tobacco companies and know the unique challenges they are facing.

Leaf hands, loose leaf, tipped and butted tobacco, threshed, dried and packed tobacco – the production stages that tobacco passes through all have very different application requirements.

Our non-toxic belts are designed specifically to suit these applications and perform reliably, repeatedly and economically.

Year after year, FDA EU and Pyrolysis regulations become stricter. To help the industry conform, Ammeraal Beltech supplies high-quality halogen-free and nitrogen-free non-toxic belts offering outstanding production performance for greater process reliability and increased throughput.

Read more

Primary processing belts need to be hard-wearing and highly resistant to casing and flavouring liquids. They should also be low noise, easy to clean and deliver a long service life.

Read more

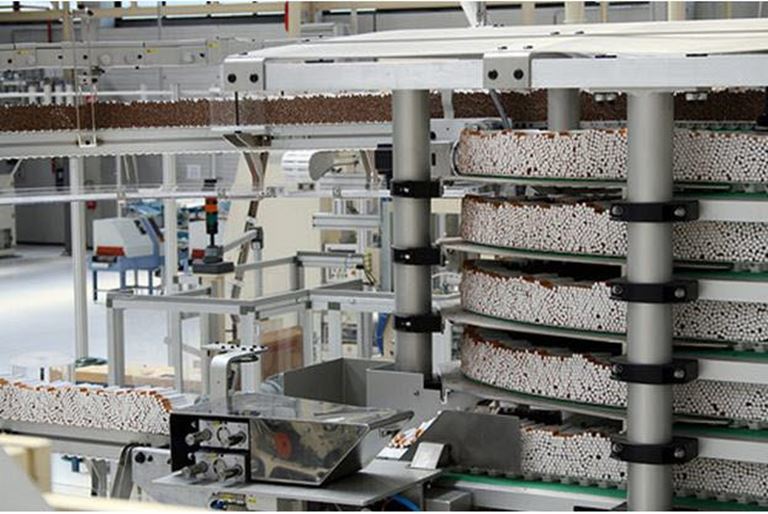

Secondary Manufacturing Processes for cigarette production require special belting properties. All applications with direct tobacco contact must have non-toxic solutions, while the transfer of cigarettes into packaging machines and of cigarette packets from bundlers / cartoners into case packers and palletizers require belts with low or high-grip properties.

Read more