Global

International

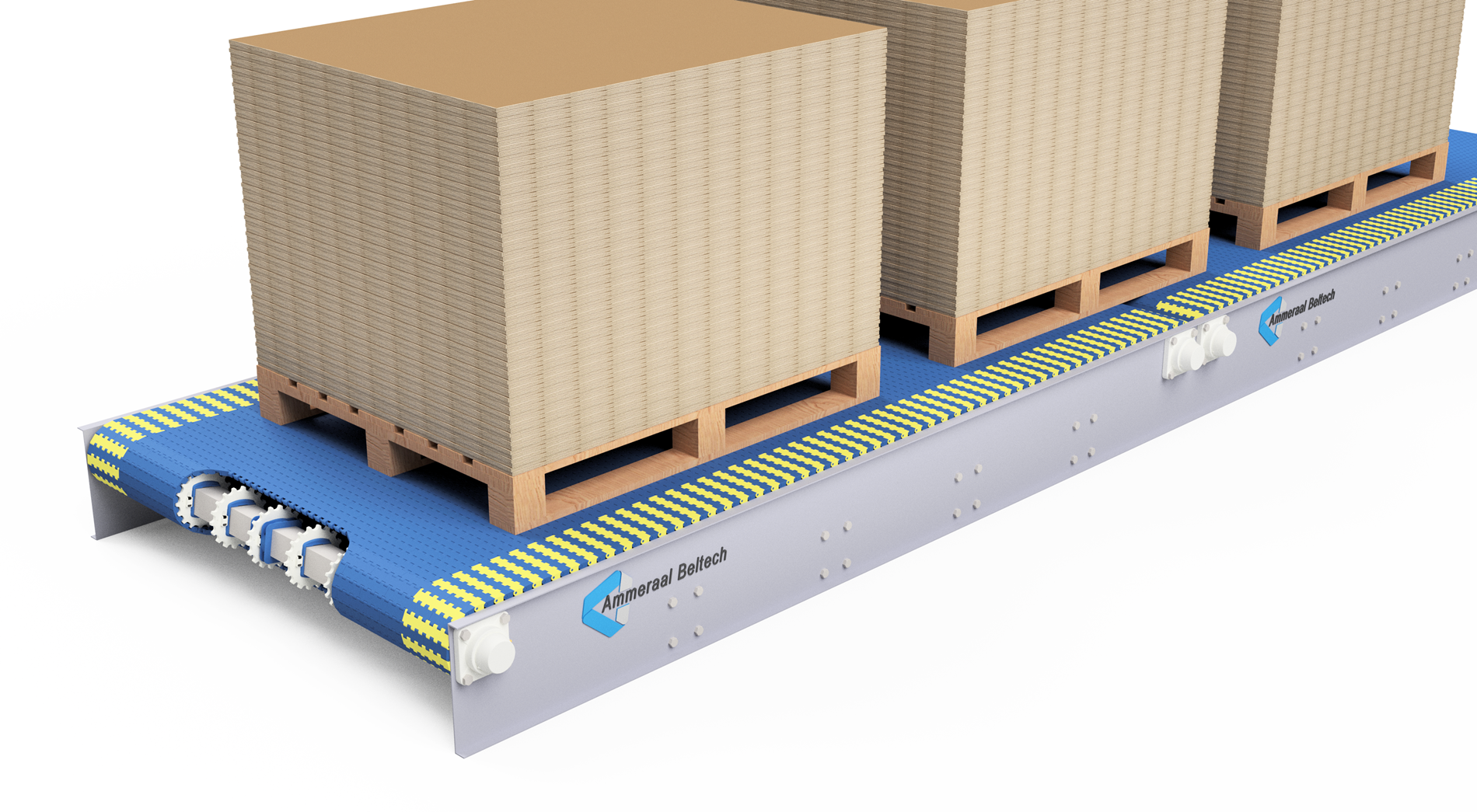

To ensure we provide belts that meet the industry standards and to accommodate our ever-expanding range of chains and components, we are excited to introduce the latest addition to our modular belting lineup – uni ITB (Industrial Thick Belt).

This belt is meant for heavy loads in abrasive environments where wear and impact resistance are crucial for productivity and streamlined operations. It is easy to mount thanks to the uni Lockpin system and even easier when complemented with UltraFit® two-part sprockets. ITB can also run on standard sprockets.

Curious to learn more? Read on!

Product details

The belt’s pitch is 1.0" and the thickness equals 0.5". A smaller pitch minimises the polygonal effect, reducing tension fluctuations and enabling smaller inline transfer gaps for precise and consistent product conveying.

The heavy-duty thickness significantly boosts load capacity, ensuring it can withstand the wear of the most demanding manufacturing processes.

Top surface flatness enhances product stability and the solid closed hinge on the underside of the link enhances the belt's wear resistance, and weight distribution.

The uni ITB can smoothly run in both directions.

UltraFit® Two-part sprocket system – how does it work?

As mentioned before, uni ITB can run on UltraFit® two-part sprockets.

The UltraFit® system saves time and cuts costs with its built-in interchangeable adapters, ensuring perfect sprocket alignment across the belt width. These adapters come in two sizes: 25.0 mm (0.98 in) and 76.0 mm (2.99 in). Additionally, for the ITB, the UltraFit® is available with 16, 18, and 21 teeth, featuring adapters that fit both Metric and Imperial bore sizes for compatibility with most existing systems.

UltraFit® system offers several key benefits, including quick and simple sprocket installation or replacement, and easy belt re-alignment for improved performance, thanks to its adapters. The belt replacement can be done by just one person, eliminating the need for heavy lifting and increasing safety. The system ensures outstanding performance and reliability, increasing efficiency while reducing maintenance costs.

The belt can be up and running in 30 minutes!

Learn More About uni ITB

For more detailed insights into how the uni ITB can optimize your industrial operations, improve efficiency, reduce downtime, and lower overall operational costs for your facility, click here.