Global

Kansainvälinen

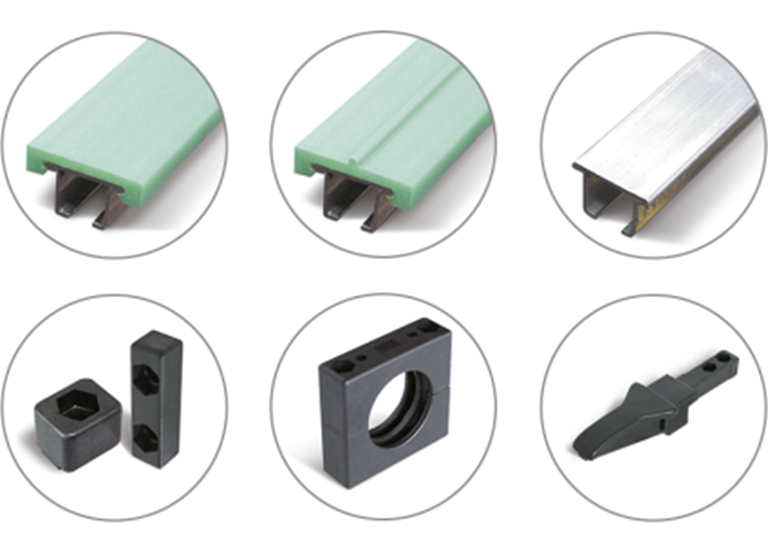

Enhance the efficiency and durability of your conveyor systems with our extensive selection of conveyor profiles, wearstrips, and guides. Our top-quality and high-density products are engineered to withstand heavy use, low friction and ensure smooth operation. Overall increases the duration and conservation of every conveying part.

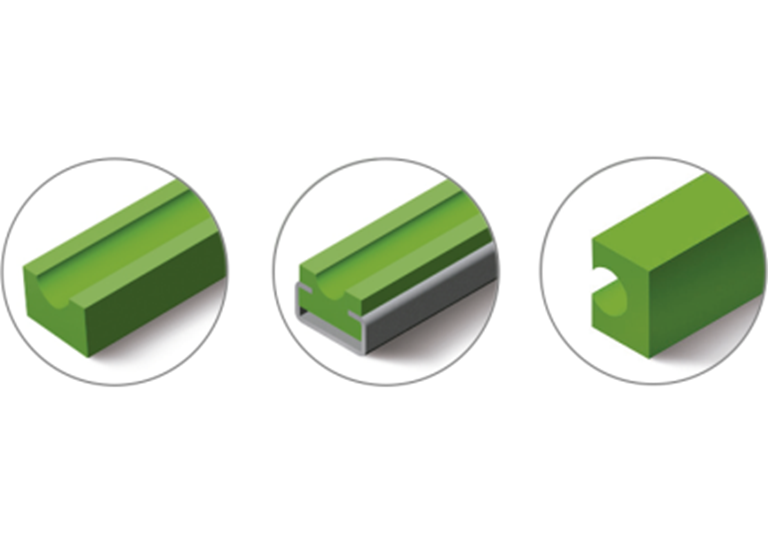

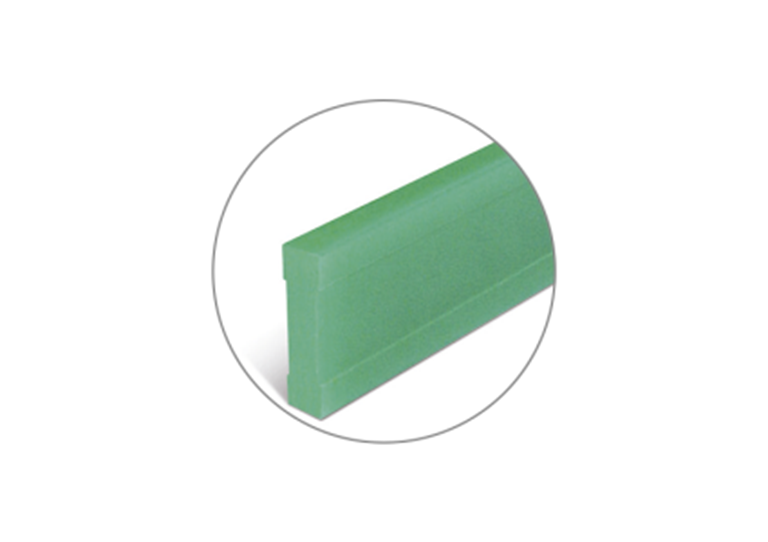

Wearstrips, also known as chain and belt guides, help to keep your conveyor system running smoothly by reducing friction and wear. Our selection of wearstrips includes various sizes and materials to suit a wide range of applications. The wearstrips support the stability of processes and helps in reducing the drive energy used by conveying processes.

Our cutting-edge extrusion technologies can create slide profiles with complex geometries that are not feasible through machining. Depending on the cross-section of the profile, this technique may offer better cost-effectiveness and technically viable options.

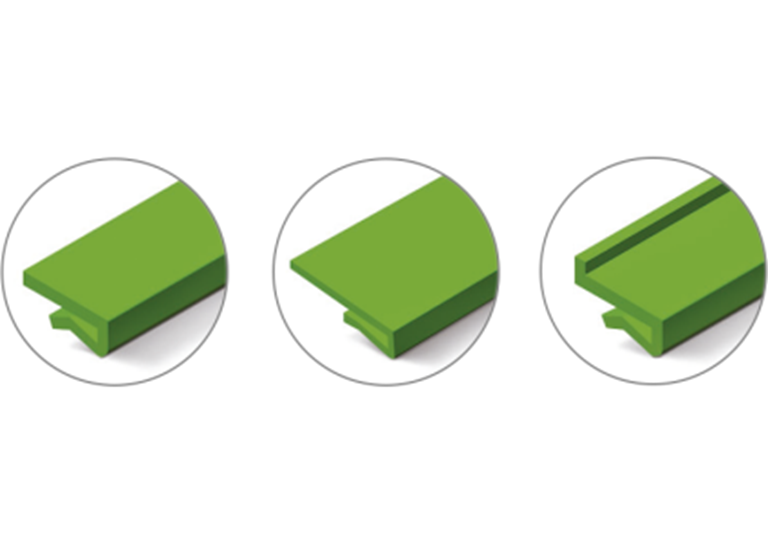

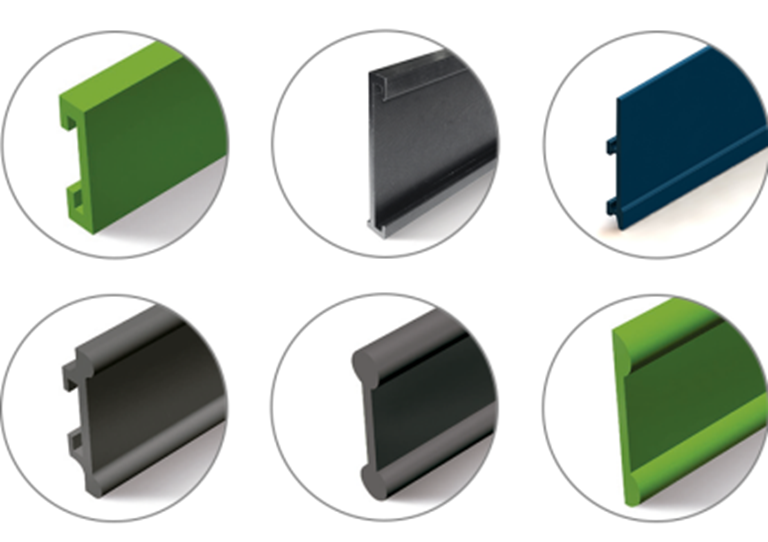

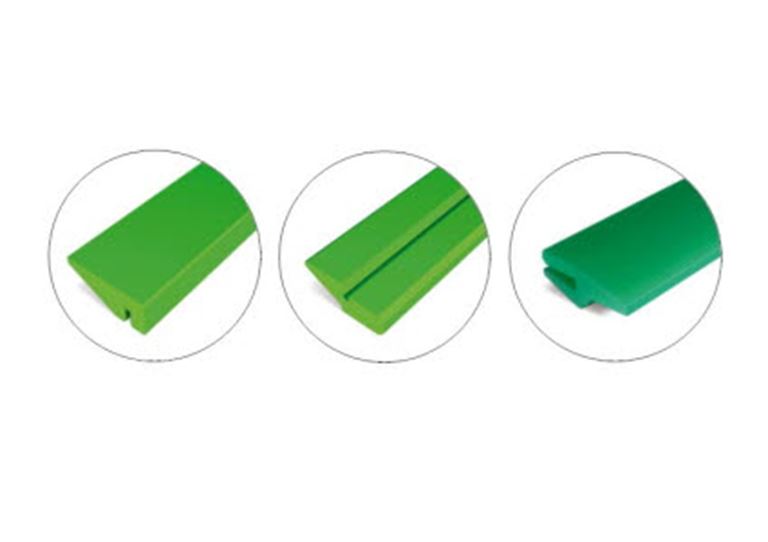

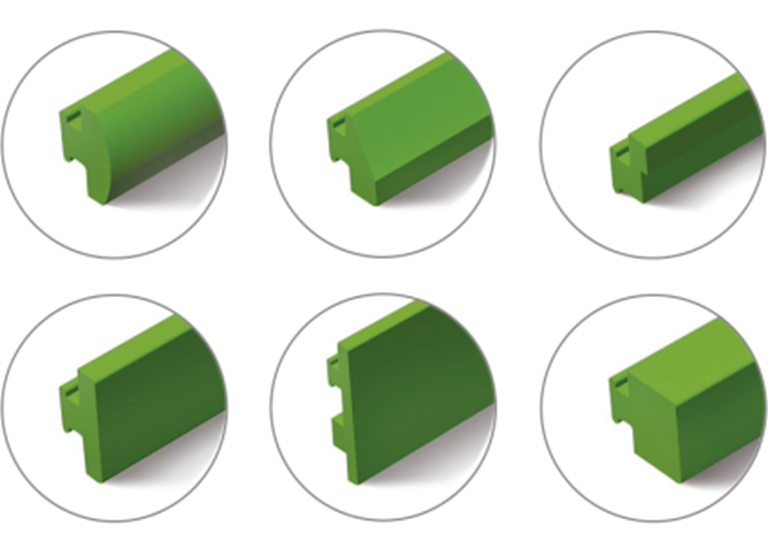

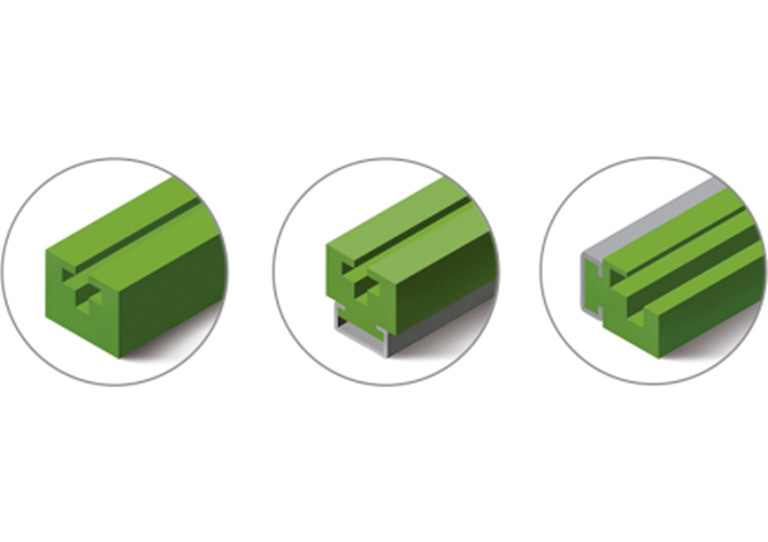

Special shape wearstrips guide the chain or belt along the designated path, reducing friction and wear on the chain or belt while protecting the conveyor structure from damage caused by contact.

Specifications

On Demand Options

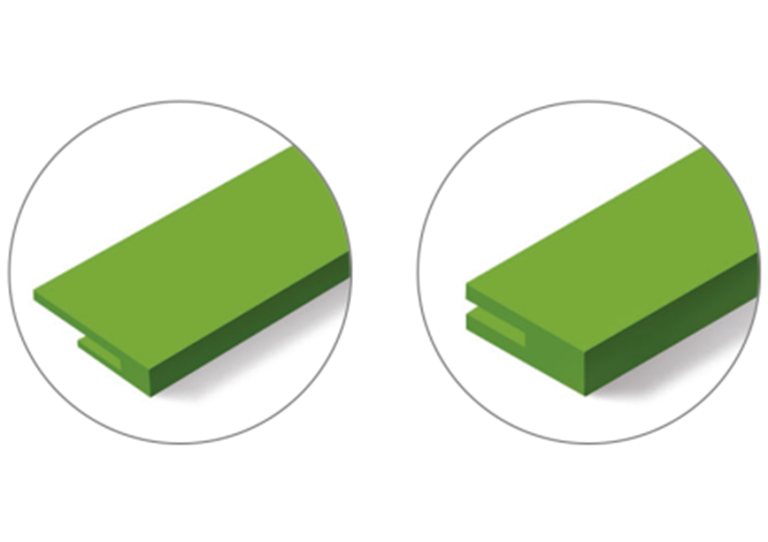

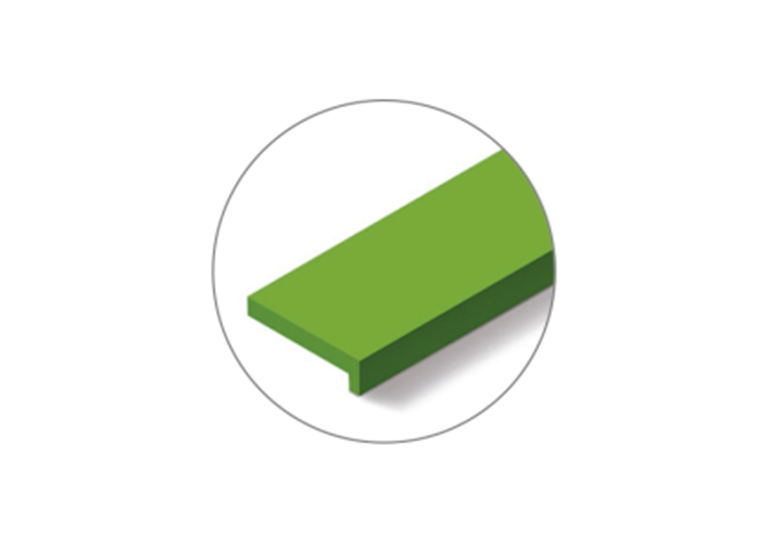

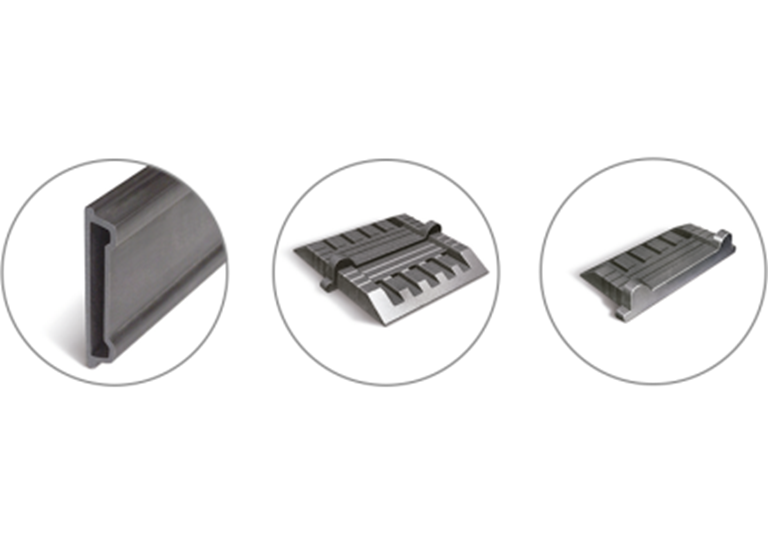

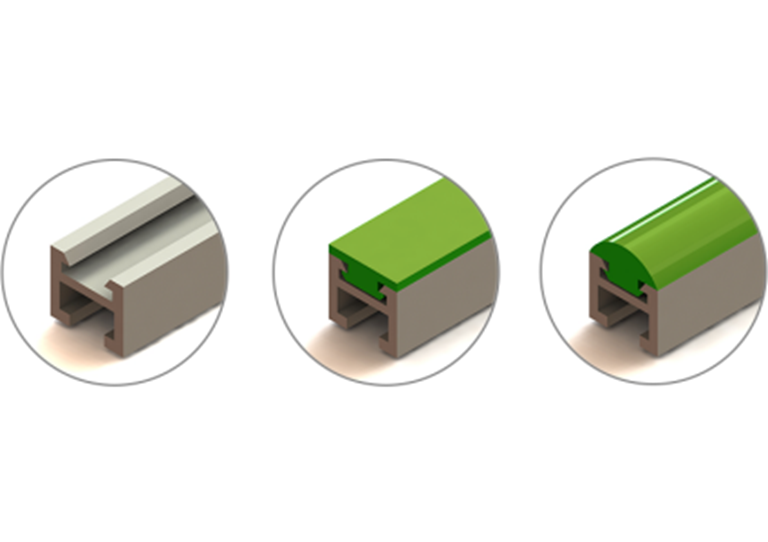

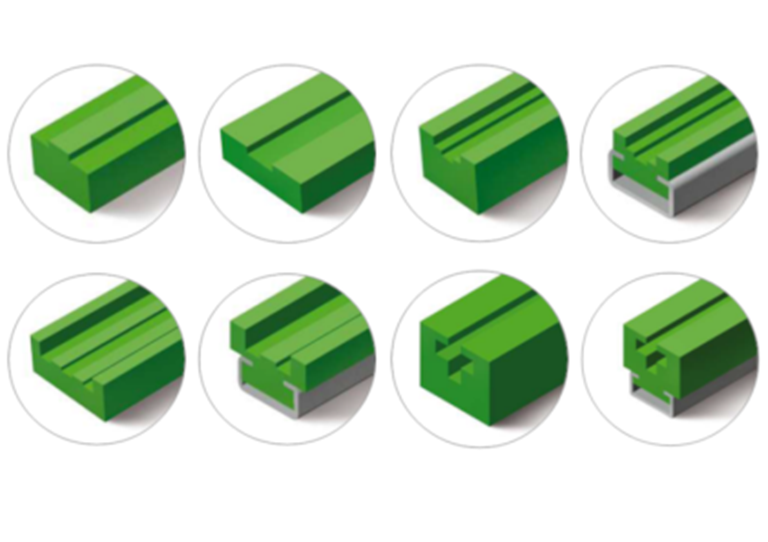

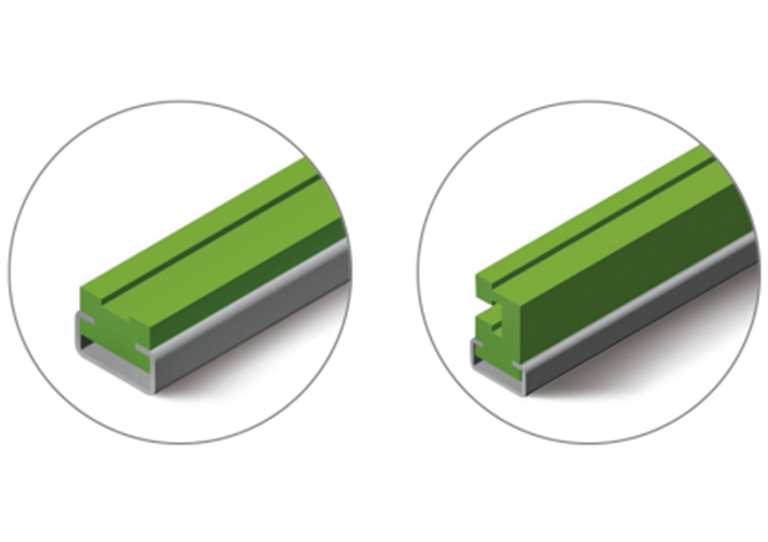

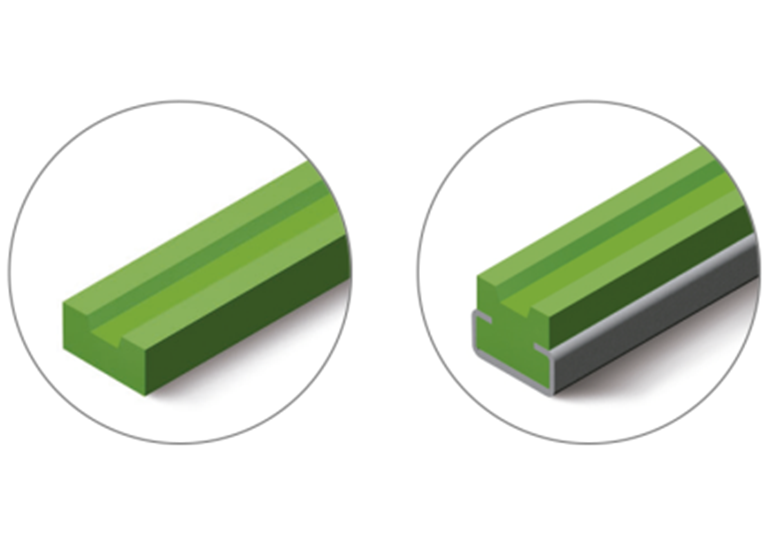

Plate cover profiles are clipped onto the metal plate frame, supporting belts along its designated path. This helps to minimize friction and wear on the belt, while also protecting the conveyor structure from potential damage due to contact.

Specifications

On Demand Options

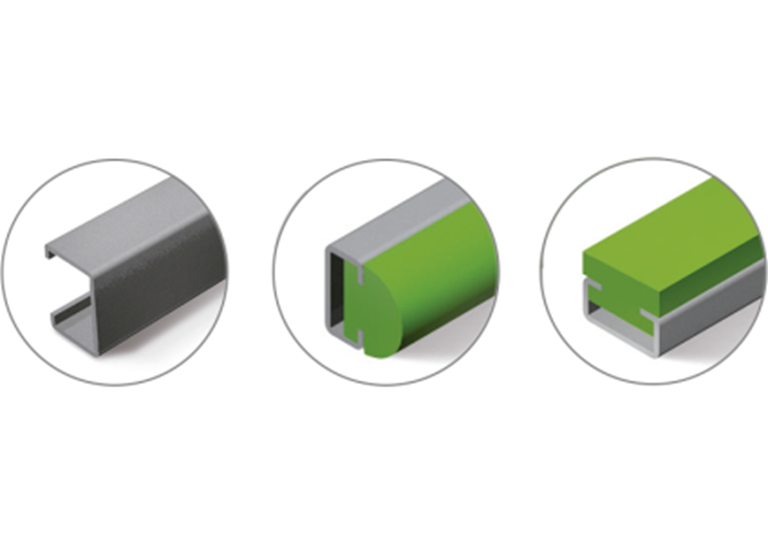

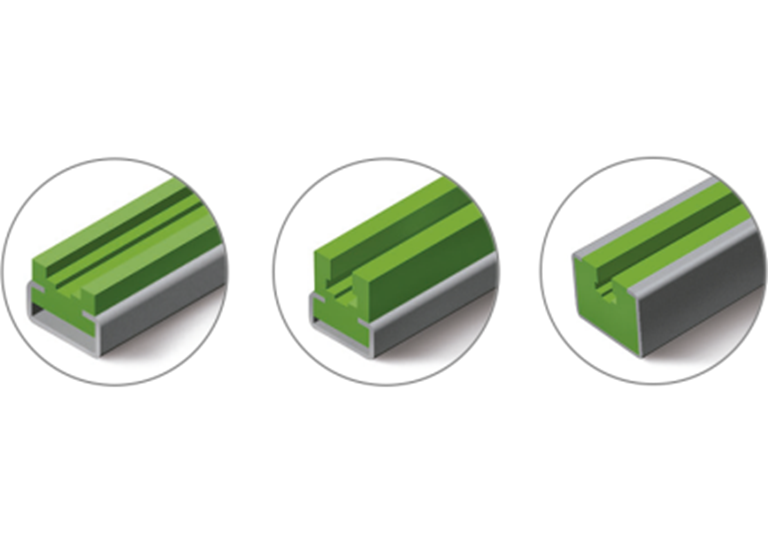

"U" shaped wearstrips are fitted onto the metal plate frame, supporting chains or belts along its designated path. This helps to minimize friction and wear on the chains or belt, while also protecting the conveyor structure from potential damage due to contact.

Specifications

On Demand Options

The C2919 steel or aluminium guide is commonly used to attach the wearstrips to the conveyor frame. It is designed to clip onto the wearstrips and be bolted to the conveyor frame easily, holding the wearstrips securely in place. This ensures that the wearstrips remains in the correct position and does not move or shift during operation.

The C2919 guide should be assembled with the appropriate accessories.

Specifications

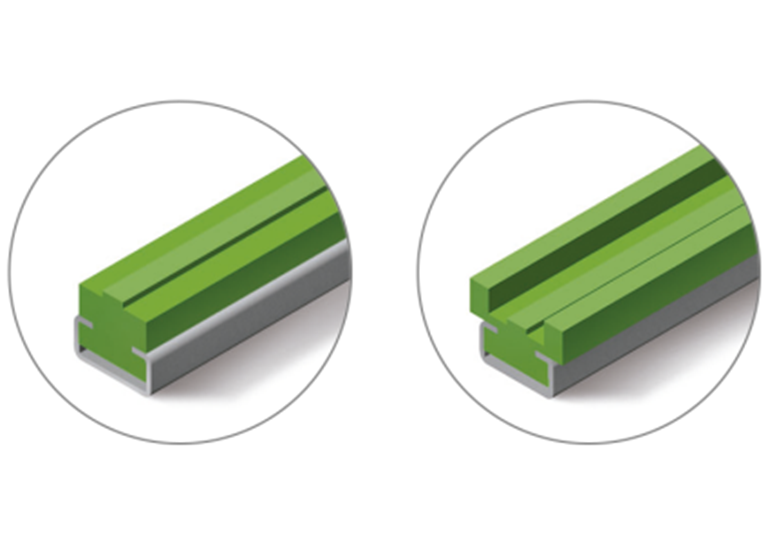

"P" shaped wearstrips are clipped onto the metal plate frame, guiding the chain or belt along its designated path. This helps to minimize friction and wear on the chain or belt, while also protecting the conveyor structure from potential damage due to contact.

Specifications

On Demand Options

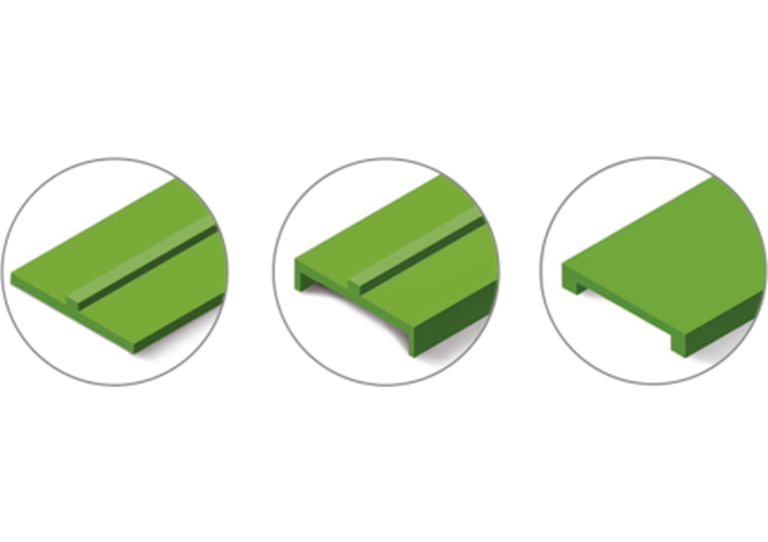

“L” shape wearstrips guide the chain or belt along the designated path, reducing friction and wear on the chain or belt while protecting the conveyor structure from damage caused by contact.

Specifications

On Demand Options

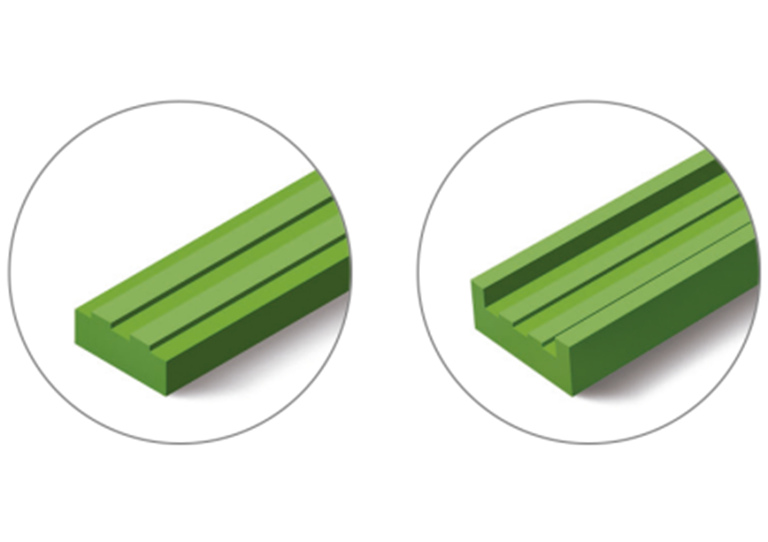

“Z” shape wearstrips guide the chain or belt along the designated path, reducing friction and wear on the chain or belt while protecting the conveyor structure from damage caused by contact.

Specifications

On Demand Options

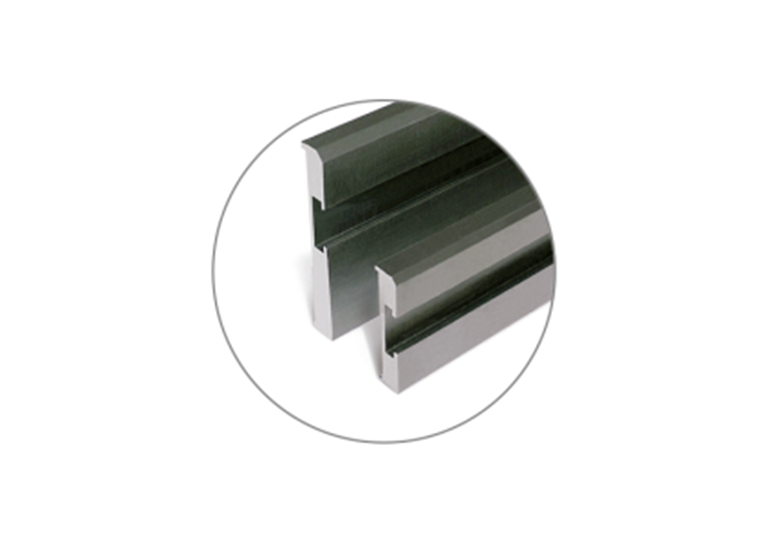

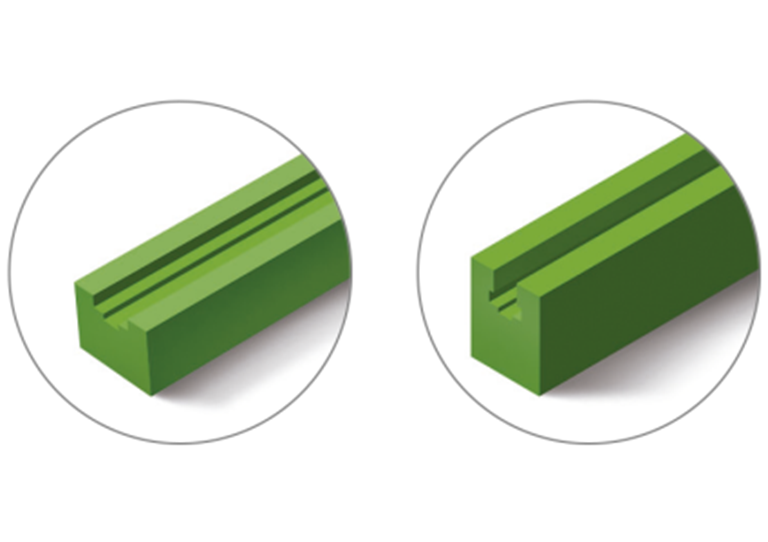

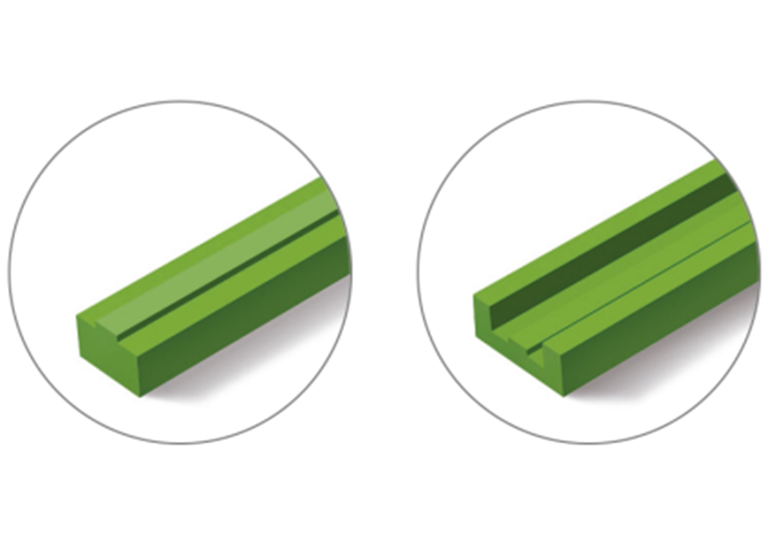

This profile supports the returning chain along the designated path, reducing friction and wear on the chain. To improve Performance this profile should be assembled with the appropriate accessories.

Specifications

View the recommended accessories for this profile.

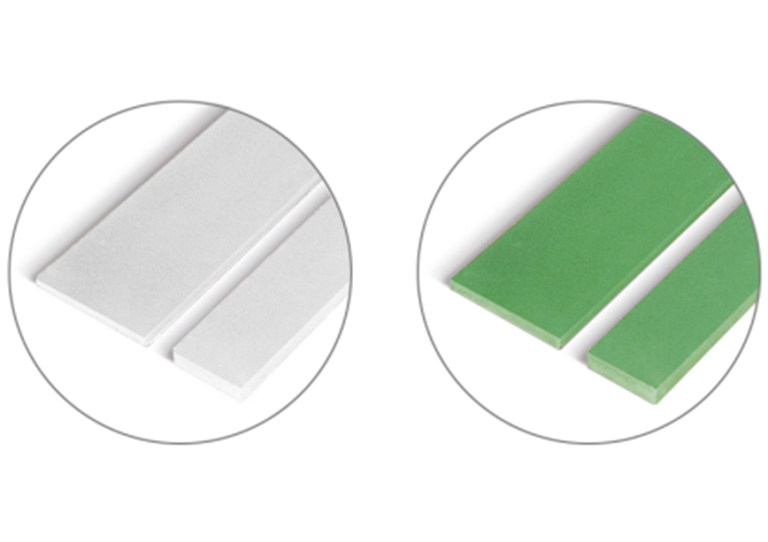

Flat shape wearstrips guide the chain or belt along the designated path, reducing friction and wear on the chain or belt while protecting the conveyor structure from damage caused by contact.

Specifications

On Demand Options

Side guide rails, also known as product guide rails, help to guide products along the conveyor system. Our selection includes a variety of sizes and materials to fit your specific needs.

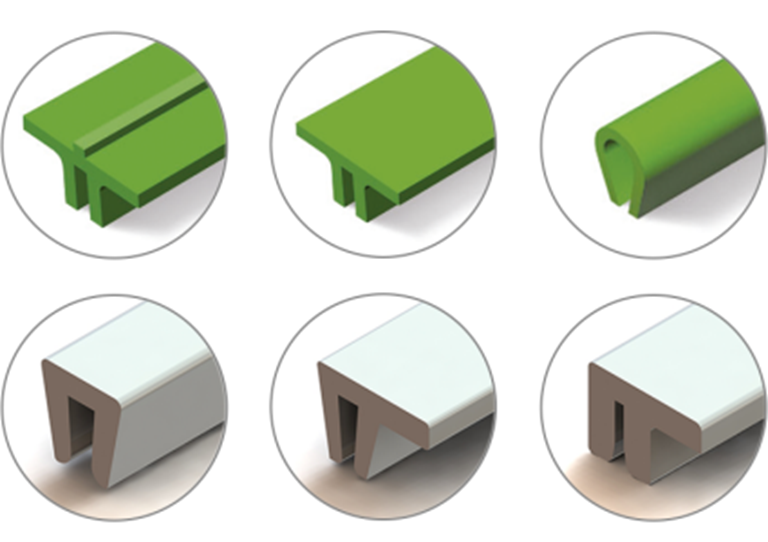

These profiles guide and support products along the conveyor line. They are normally screwed or clipped onto a metal plate, which is then connected to the side bracket and conveyor frame, providing strength and rigidity to the profile.

Specifications

On Demand Options

These profiles guide and support large volumes of products along the conveyor line. To provide strength and rigidity, they require a metal plate inside. Additionally, a special clamp is needed to connect the profile to the side bracket and conveyor frame.

Specifications

The conical metal guide with UHMW-PE inserted is used to support and direct products on a conveyor system. Its conical shape allows for easy clamping to the side bracket, while the UHMW-PE material reduces friction and wear on the products. Some models are also designed to guide chains and belts.

Specifications

On Demand Options

The A12052 aluminium guide with UHMW-PE inserted is used to support and direct products on a conveyor system. Its shape allows for easy screwing to the side bracket, while the UHMW-PE material reduces friction and wear on the products.

Specifications

The C2010 guide with UHMW-PE inserted is used to support and direct products on a conveyor system. Its “C” shape allows for easy clamping to the side bracket, while the UHMW-PE material reduces friction and wear on the products.

Specifications

The machined design allows for precise and consistent guiding of the products, ensuring a smooth and efficient operation of the conveyor system.

Specifications

The bar cover is a "C"-shaped profile that protects products from wear by covering side guide bars or tubes, ensuring smooth and gentle transportation on the conveyor system.

Specifications

Neck guide profiles are used in air conveyors to guide and support plastic bottles or containers as they are transported along the conveyor line to prevent them from tipping over or getting misaligned.

Specifications

On Demand Options

The UHMW-PE profiles are used in conveyor systems to guide and support products as they move along the conveyor line, reducing wear and tear on the transported products and preventing misalignments or jams.

Specifications

Roller chain guides help to keep your roller chain properly aligned and running smoothly. Our selection includes a variety of sizes and materials to fit your specific needs.

These guides are used to support and guide the roller chain horizontally, ensuring smooth and accurate movement while keeping the chain properly aligned.

Specifications

|

Chain ISO |

Pitch |

|

06B |

3/8 in |

|

08B |

1/2 in |

|

10B |

5/8 in |

|

12B |

3/4 in |

|

16B |

1 in |

|

20B |

1 1/4 in |

|

24B |

1 1/2 in |

|

28B |

1 3/4 in |

|

32B |

2 in |

These guides are used to support and guide the roller chain horizontally, ensuring smooth and accurate movement while keeping the chain properly aligned.

Specifications

|

Chain ISO |

Pitch |

|

06B |

3/8 in |

|

08B |

1/2 in |

|

10B |

5/8 in |

|

12B |

3/4 in |

|

16B |

1 in |

|

20B |

1 1/4 in |

|

24B |

1 1/2 in |

|

28B |

1 3/4 in |

|

32B |

2 in |

These guides are used to support and guide the roller chain horizontally, ensuring smooth and accurate movement while keeping the chain properly aligned.

Specifications

|

Chain ISO |

Pitch |

|

06B-1 / 06B-2 |

3/8 in |

|

08B-1 / 08B-2 |

1/2 in |

|

10B-1 / 10B-2 |

5/8 in |

|

12B-1 / 12B-2 |

3/4 in |

|

16B-1 / 16B-2 |

1 in |

These guides are used to support and guide the roller chain horizontally, ensuring smooth and accurate movement while keeping the chain properly aligned.

Specifications

|

Chain ISO |

Pitch |

|

06B-1 |

3/8 in |

|

08B-1 |

1/2 in |

|

10B-1 |

5/8 in |

|

12B-1 |

3/4 in |

|

16B-1 |

1 in |

|

20B-1 |

1 1/4 in |

|

24B-1 |

1 1/2 in |

|

28B-1 |

1 3/4 in |

|

32B-1 |

2 in |

These guides are used to support and guide the roller chain horizontally, ensuring smooth and accurate movement while keeping the chain properly aligned.

Specifications

|

Chain ISO |

Pitch |

|

06B-3 |

3/8 in |

|

08B-3 |

1/2 in |

|

10B-3 |

5/8 in |

|

12B-3 |

3/4 in |

|

16B-3 |

1 in |

|

20B-3 |

1 1/4 in |

|

24B-3 |

1 1/2 in |

|

28B-3 |

1 3/4 in |

|

32B-3 |

2 in |

These guides are used to support and guide the roller chain horizontally, ensuring smooth and accurate movement while keeping the chain properly aligned.

Specifications

|

Chain ISO |

Pitch |

|

06B-2 |

3/8 in |

|

08B-2 |

1/2 in |

|

10B-2 |

5/8 in |

|

12B-2 |

3/4 in |

|

16B-2 |

1 in |

|

20B-2 |

1 1/4 in |

|

24B-2 |

1 1/2 in |

|

28B-2 |

1 3/4 in |

|

32B-2 |

2 in |

These guides are used to support and guide the roller chain horizontally, ensuring smooth and accurate movement while keeping the chain properly aligned.

Specifications

|

Chain ISO |

Pitch |

|

06B-1 |

3/8 in |

|

08B-1 |

1/2 in |

|

10B-1 |

5/8 in |

|

12B-1 |

3/4 in |

|

16B-1 |

1 in |

|

20B-1 |

1 1/4 in |

|

24B-1 |

1 1/2 in |

|

28B-1 |

1 3/4 in |

|

32B-1 |

2 in |

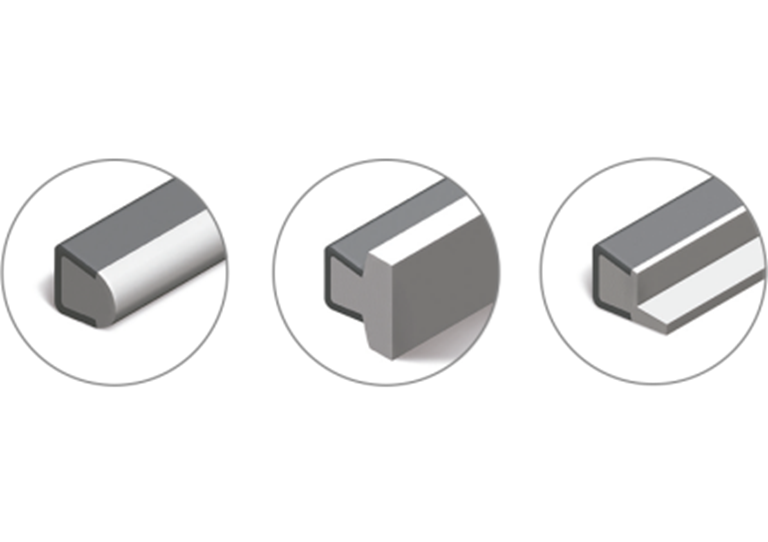

The purpose of a link chain guide is to support and guide the movement of a chain, reducing friction, minimizing wear, and ensuring proper alignment for smooth operation.

Specifications

The purpose of a flat belt guide is to support the movement of the belt reducing wear for efficient power transmission.

Specifications

The purpose of a V-belt guide is to support and guide the movement of the belt, ensuring proper alignment, and minimizing wear for efficient power transmission.

Specifications

The purpose of a round belt guide is to support and guide the movement of the belt, ensuring proper alignment, and minimizing wear for efficient power transmission.

Specifications