Globális

Nemzetközi

Important news for the bakery, beverage, and glass container manufacturing industries. There is a new chain series available from our modular belts range.

To meet the challenges in cooling deformation and chain weight, we’ve made improvements to the products we already have in our product portfolio, and developed a new, thicker, but lighter conveyor chain series.

Read on to learn more about it!

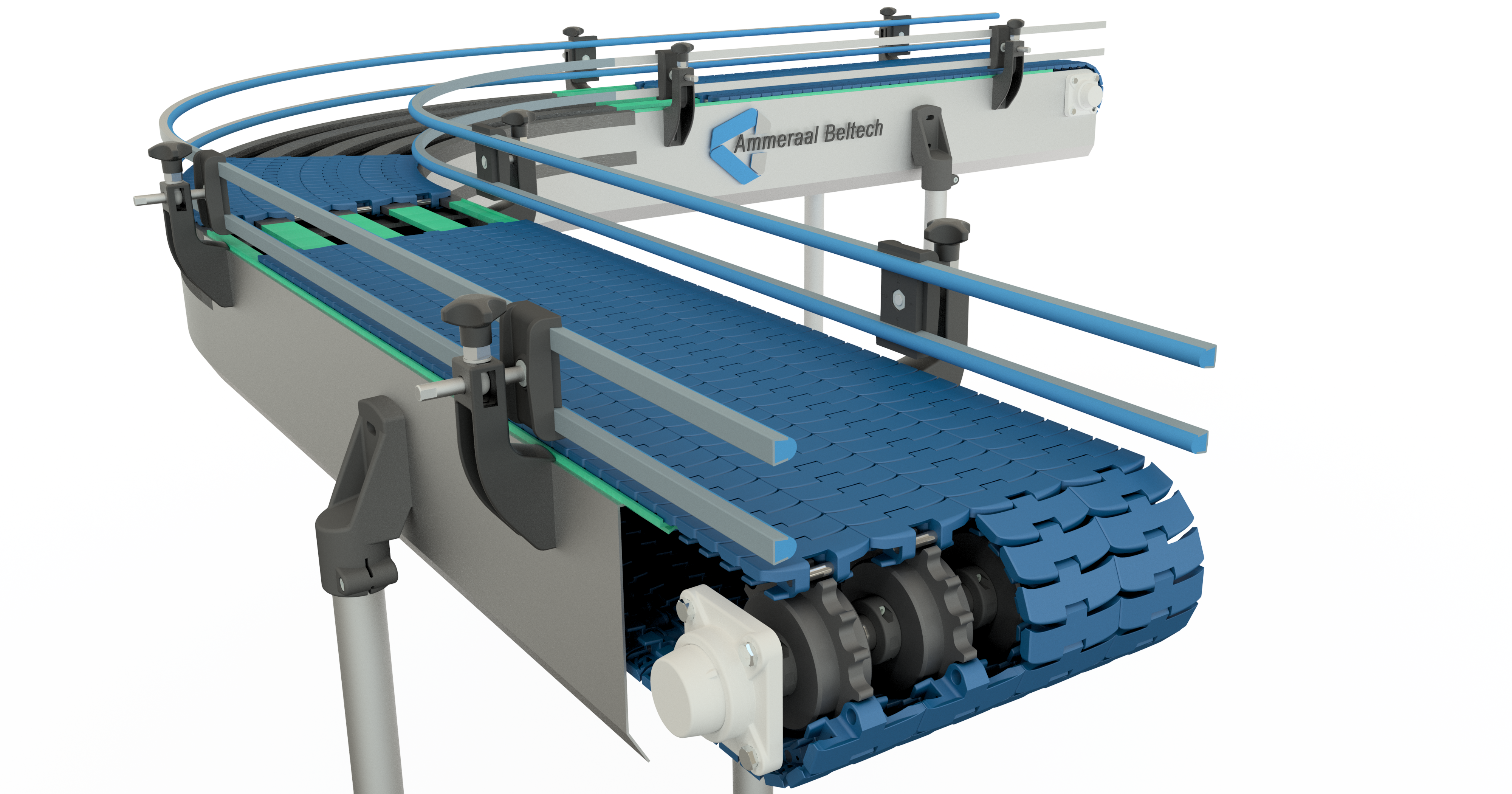

The uni 253 and uni 255 are modular plastic chains that have been designed with a specific emphasis on plate thickness to overcome the challenges faced by the bakery, beverage, and glass container manufacturing industries.

These side flexing chain series ensure exceptional product stability during lateral movements and smooth transitions between chains and modular belts, providing maximum product safety throughout the entire conveying process.

- The belt’s pitch is 25.4 mm (1" in). The thickness equals 8.7 mm (0.34 in) for uni 253 and 12.7 mm (0.5 in) for uni 255.

- Bevel, TAB, and magnetic hinges are available for uni 253. TAB and magnetic hinges are available for uni 255.

- The top surface for uni 253 can be flush grid (FG) or flat top (FT). The top surface for uni 255 is flat top (FT).

- The belt fits industry standard 880 / 879 / 881 conveyor track.

- There are supporting products available. Sprockets are a must, and there are also components such as curves, tracks, wearstrips, etc.

For the detailed product and components range as well as CAD drawings, you can refer to the product page for chain belts. Please note that there are sizes available upon request – such as tooth sizes in sprockets. If you need a customized solution, do not hesitate to reach out.

The series is available in different materials. Below you can learn more about the materials and colors used for this new chain and how their features suit the belt's purpose:

POM D – standard blue food-grade material for chains for general applications.

PA6 – black food-grade thermoplastic material meant for bakery and glass bottling. Very strong, stiff, with a high resistance to wear.

PA6.6-GFH – black food-grade heat-stabilized thermoplastic material with glass fiber reinforcement. It's even more resistant to wear, as the glass fiber contributes to increasing these properties. Its maximum permissible working temperature is 180 °C.

POM-DK – dark grey reinforced POM material - acetal with Kevlar enhanced lubrication for food containers, one-way glass bottles high-speed dry applications, or bottling (PET case packers/palletizers). It provides lower friction and better wear resistance in the long term.

The standard default pin material for all 253 and 255 chains is stainless steel.

- Optimal performance and reliability – the chains can be used in a wide range of applications, low and high speed, as well as mass and single conveyors on both side-flexing and straight-running lines.

- Ultimate wear resistance – heavy-duty thickness withstands high workload capacity.

- Improved stability of product transport and lateral transfers and less pulsation risk and polygonal effect. It’s all thanks to top-flight flatness and reduced gaps between links. The series optimizes container handling and minimizes downtime caused by product spillage.

- Reduced total cost of ownership and energy efficiency. The belt is lightweight, but without compromising strength.

These series are designed to withstand high working temperatures and abrasive environments. Here are examples of typical applications where uni 253 / 255 can shine:

- Multi-strand conveyor systems – straight and side-flexing sections combined on a single conveyor.

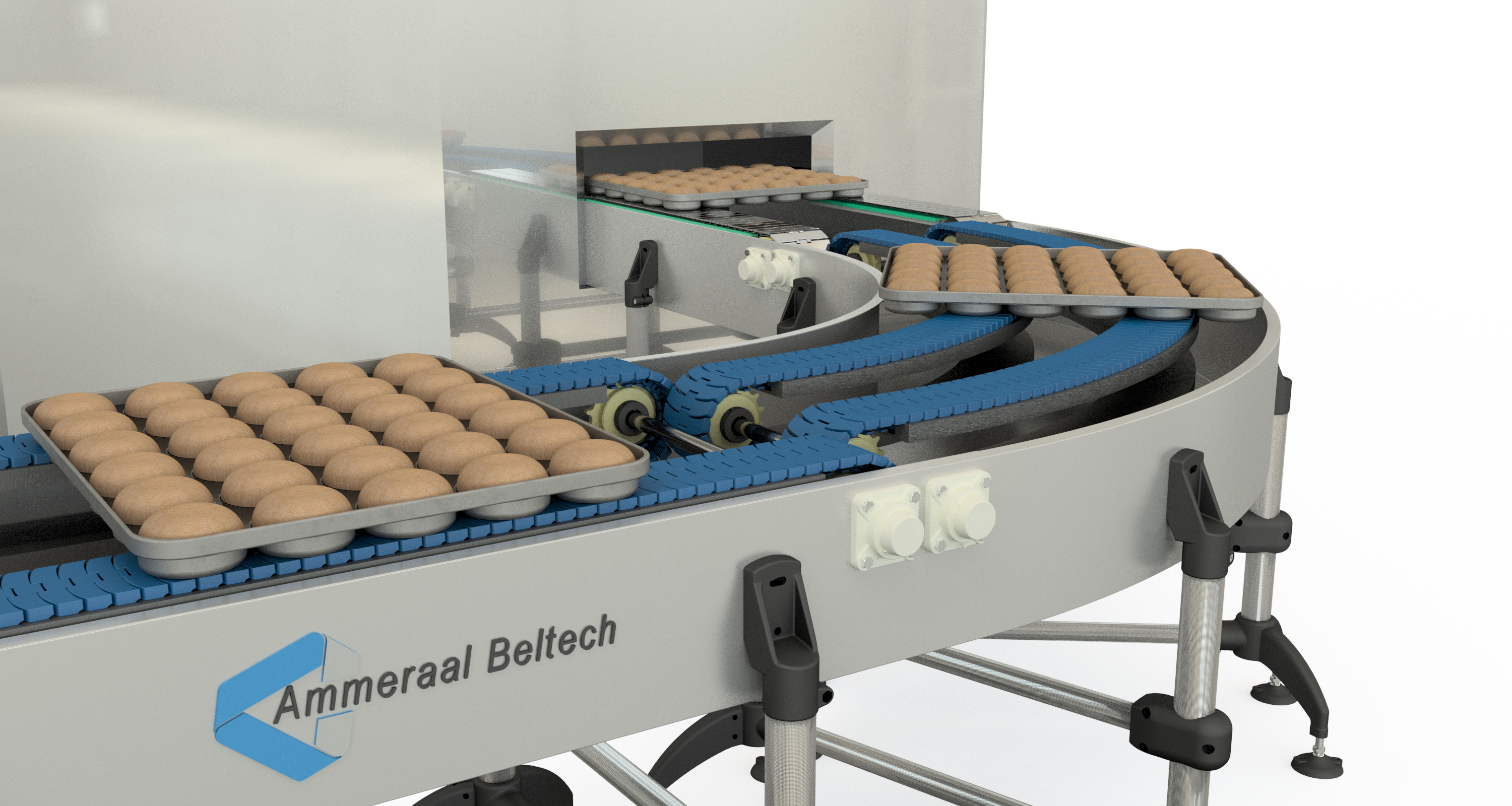

- Bakery industry – pan handling systems and lid handling systems.

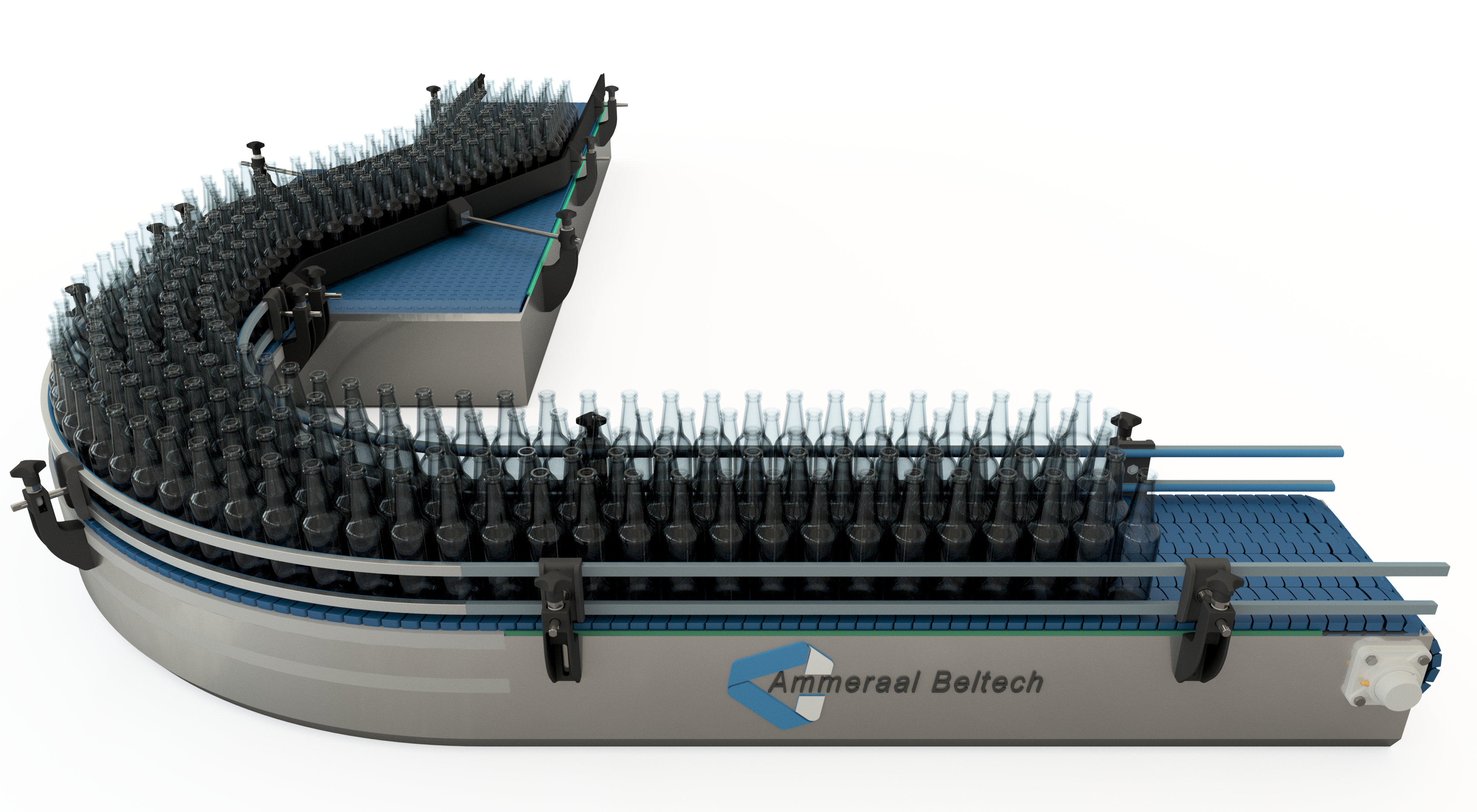

- Beverage industry – wine bottling, soft drinks, water, beer processing lines.

- Glass container manufacturing plants, returnable glass processing lines, filler applications.

uni 253 / 255 ensures smooth and reliable transport of items, minimizing the risk of breakage and ensuring consistent output.

Get in touch with our sales team to discuss the product details and see how it can optimize your processes!