Ammeraal Beltech is excited to announce the expansion of our modular portfolio with the launch of three new products: the uni ITB modular belt, and the uni 253 and uni 255 belt chains. These additions are engineered to meet the evolving demands of various industries, including bakery, beverage, corrugated and glass container manufacturing. The new products offer superior performance, durability, and versatility, ensuring that your operations run smoothly and efficiently.

uni Industrial Thick Belt (ITB)

The uni Industrial Thick Belt, or ITB, is proudly molded and assembled in Reading, Pennsylvania, exemplifying our commitment to bringing more production to the U.S. and being Built American Proud. This heavy-duty, straight-running modular belt is perfect for demanding applications, including bakery, beverage, tire, and corrugated industries. Key features of the uni ITB include:

- Enhanced Stability: A 0.5 inch thickness, a 1.0 inch pitch, and smooth flat top surface ensure consistent motion and maximum product stability. When paired with the uni 255 chain, the uni ITB facilitates seamless lateral transfers, making it perfect for applications that require precise product movement.

- Superior Wear Resistance: The solid closed hinge design and high-quality uni lockpin provide excellent protection against abrasive contamination, reducing pin wear and extending the belt's lifespan.

- Seamless Integration: The uni ITB offers compatibility with existing conveyor systems, allowing for seamless integration into current setups and eliminating the need for any conveyor design modifications.

uni 253 and 255 Chains

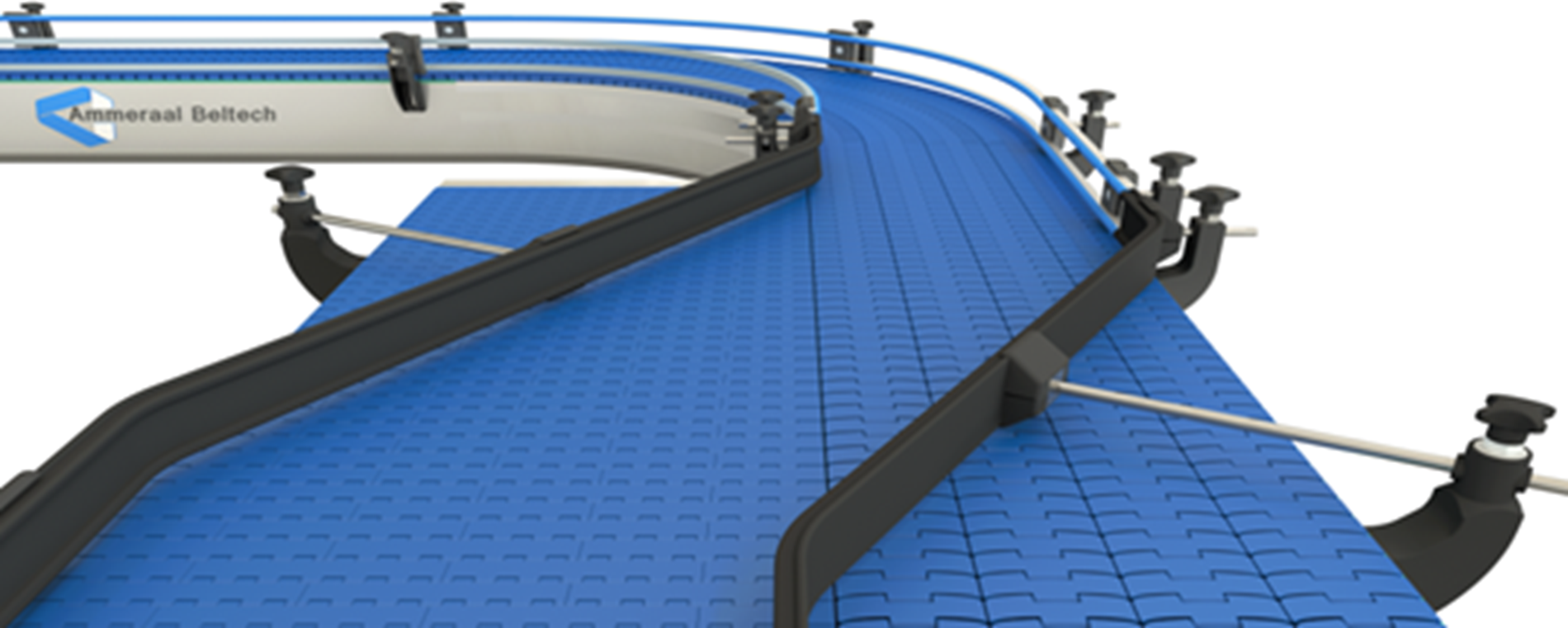

The uni 253 and 255 chains are the latest innovations in our side-flexing modular chain belt range. Designed with a focus on plate thickness, these chains offer unique benefits suited to different operational needs.

- Plate Thickness: The uni 253 chain features a thickness of 0.34 inches, offering a balance of strength and flexibility, making it suitable for standard applications. The uni 255 chain, with a thickness of 0.5 inch, provides additional durability and stability, ideal for more demanding environments.

- Hinge Types: The uni 253 is available with bevel, TAB, and magnetic hinges, while the uni 255 offers TAB and magnetic hinge options. These variations ensure that the chains can be tailored to specific applications and operational needs.

- Material Options: The chains are available in materials such as POM-D, PA6.6, and PP, each offering unique properties like low friction, high strength, and suitability for high-temperature applications.

Applications and Benefits

- Wide Range of Applications: The uni ITB, 253, and 255 chains are versatile solutions for various industries, including multi-strand conveyor systems, bakery pan handling, beverage bottling, glass container manufacturing, and more. The ITB excels in straight-running applications, while the 253 and 255 chains are designed for side-flexing, ensuring smooth transitions and consistent product handling when used together.

- Reduced Maintenance and Downtime: The innovative design of the ITB uni lockpin system ensures easy installation and removal, significantly reducing maintenance time and costs. The compatibility of these products with existing conveyor designs allows for straightforward integration, making them ideal for enhancing current setups.

- Safety and Efficiency: The closed flat top design, combined with reduced gaps between links, minimizes the risk of product spillage, enhancing workplace safety. The lightweight nature of the uni ITB, 253, and 255 chains also contributes to reduced energy consumption, optimizing operational costs.

- Supporting Products: To enhance the performance and ease of installation, the uni ITB is complemented by the uni UltraFit® Two-Part Sprocket. This sprocket design simplifies the installation and alignment process, allowing for quick and accurate setup without the need for special tools. This innovation reduces downtime and enhances belt performance, making it a valuable addition to any conveyor system. Learn More about the uni UltraFit® Two-Part Sprocket here.

Investing in U.S. Production and Inventory

At Ammeraal Beltech, we've made significant investments in our Chains & Components Program to better serve our customers. The new uni ITB is proudly molded and assembled in the U.S., ensuring superior quality and faster delivery times. For the uni 253 and 255 chains, our expanded U.S. storage facilities maintain a robust inventory, reducing lead times and ensuring prompt availability. Our commitment to being Built American Proud means these innovative products are designed to meet your needs with the reliability and support you deserve.

Ammeraal Beltech's latest modular belt products are designed to meet the highest standards of quality and performance. Whether you are looking to enhance your existing systems or implement new solutions, the uni ITB, 253, and 255 chains offer unmatched reliability and efficiency. Learn more about our modular belt options here.